IreStruEng

Structural

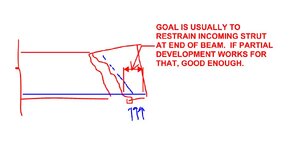

Clause 8.3.1.3 of AS 3600 states that "Not less than one half of the tensile reinforcement required at midspan shall extend past the

face of the support for a length of 12db, plus a cog or an equivalent anchorage;"

For 16mm diameter reinforcement, 12db = 192mm. Adding in cover and the thickness of the supporting wall/column is going to need be >=230mm.

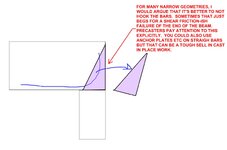

Say two 16mm dia. bars are required at midspan of a simply supported beam for the flexural reinforcement. If both bars are taken 6db (96mm) past the face of the support is that clause deemed satisfied in your opinion?

face of the support for a length of 12db, plus a cog or an equivalent anchorage;"

For 16mm diameter reinforcement, 12db = 192mm. Adding in cover and the thickness of the supporting wall/column is going to need be >=230mm.

Say two 16mm dia. bars are required at midspan of a simply supported beam for the flexural reinforcement. If both bars are taken 6db (96mm) past the face of the support is that clause deemed satisfied in your opinion?