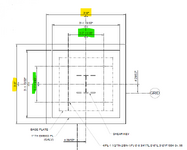

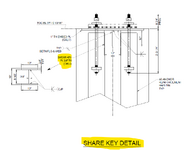

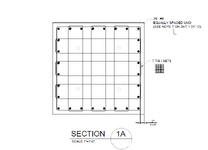

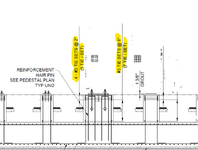

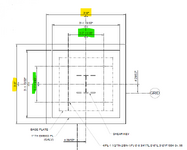

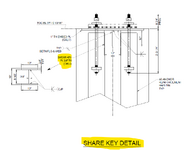

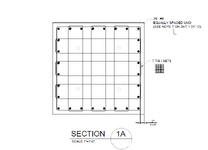

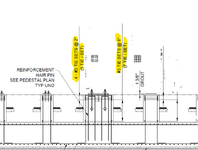

I have a shear lug/key that I am working on designing using Hilti Profis for a concrete pedestal. However, Profis is telling me that the shear lug is failing in concrete break out strength. My pedestal is 44"x44" & 40" tall, with (28)-#8 vertical rebars (see images). The tie reinf. is also shown in the images.

My shear forces acting on the pedestal are the following: Horizontal load on Pedestal (Hx) = 143.8 kips & Horizontal load on Pedestal (Hz) = 225.6 kips

If the pedestal itself has been designed to resist the shear forces based on the pedestal section, concrete strength, vertical rebar & all the ties....would it be safe to consider that the verti. reinf. & ties would be adequate to prevent concrete break out for the shear lug/key?

Suggestions/comments are appreciated.

My shear forces acting on the pedestal are the following: Horizontal load on Pedestal (Hx) = 143.8 kips & Horizontal load on Pedestal (Hz) = 225.6 kips

If the pedestal itself has been designed to resist the shear forces based on the pedestal section, concrete strength, vertical rebar & all the ties....would it be safe to consider that the verti. reinf. & ties would be adequate to prevent concrete break out for the shear lug/key?

Suggestions/comments are appreciated.