BuildWithSteel

Structural

- Apr 27, 2025

- 1

Modifying PEMB- am interested to hear what solutions others might have gone with in my situation, even if I end up regretting the final solution I landed on.

Multispan, existing pre-engineered metal building- 4 bays, 54’ wide, PEMB bents at 25’ on center- total building length about 350’ long. Interior columns are Pipe 8”- couldn’t say for certain wall thickness at time of design other than tapping the column to hear the tone of “ping” it made- it sounded thin LOL. I wouldn’t have actually trusted that “test” if I had actually planned on somehow attaching to existing columns. Exterior columns are typical built up tapered plate columns.

Assumed interior columns are pinned top and bottom for only gravity based off of light, simple beam over column cap plate connections and base plate configuration- bolts from cap plate to PEMB bent was only 1/2” diameter as an example.

I needed to remove 2 of the interior ridge line columns for a 75’ clear span.

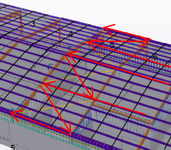

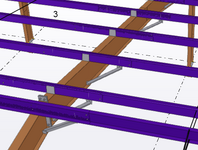

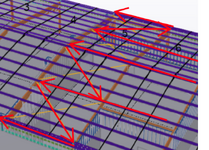

Attached photos was my solution- reinforced/enlarged the existing footings each end, 2-new pairs of columns added each end, sandwiched existing column line with a trusses braced to eachother each side as a jack beam/truss, existing columns cut out once all connections made- no shoring was needed this route. It’s not a fancy solution- one that you can look at and logically see exactly how it works. Possibly a bit overdone.

What might have you done differently in situation?

Multispan, existing pre-engineered metal building- 4 bays, 54’ wide, PEMB bents at 25’ on center- total building length about 350’ long. Interior columns are Pipe 8”- couldn’t say for certain wall thickness at time of design other than tapping the column to hear the tone of “ping” it made- it sounded thin LOL. I wouldn’t have actually trusted that “test” if I had actually planned on somehow attaching to existing columns. Exterior columns are typical built up tapered plate columns.

Assumed interior columns are pinned top and bottom for only gravity based off of light, simple beam over column cap plate connections and base plate configuration- bolts from cap plate to PEMB bent was only 1/2” diameter as an example.

I needed to remove 2 of the interior ridge line columns for a 75’ clear span.

Attached photos was my solution- reinforced/enlarged the existing footings each end, 2-new pairs of columns added each end, sandwiched existing column line with a trusses braced to eachother each side as a jack beam/truss, existing columns cut out once all connections made- no shoring was needed this route. It’s not a fancy solution- one that you can look at and logically see exactly how it works. Possibly a bit overdone.

What might have you done differently in situation?