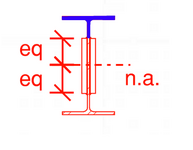

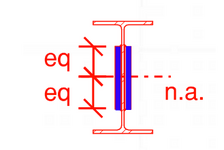

Just thinking allowed. Immediately below the top flange, there will be a shear flow in the web. Progressing down the web, the shear flow will increase. As you get to the top of the two side plates, the shear flow will suddenly be confronted with three load paths, into the side plates through the two welds and down the web. If you take the shear flow in the web at the bottom of the welds (two vertical sides), will the thickness be the two welds and the web (V.Q/[I.(2.t+w)]? One or two have posted something similar.

Edit: the weld thicknesses could be at the 45 degree plane (min weld section).

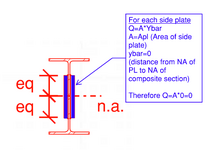

Edit: After reading a few more posts, I've noted that some are discussing the use of pins / bolts along the N/A, without welds. I understand this approach (zero axial strain, vertical shear only, etc). The comment made in this post was based on the original question, namely the use of welds.