Hi All,

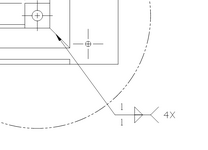

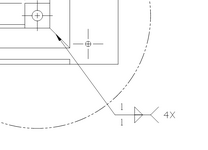

I’m still relatively new to AWS welding symbols and need some help understanding the one below. I’ve searched through various references but couldn’t find a clear explanation.

From what I can tell, it looks like a fillet weld, but that seems incorrect since the joint is a butt joint. Also, I’m unsure what the number “1” refers to in this context.

I’m still relatively new to AWS welding symbols and need some help understanding the one below. I’ve searched through various references but couldn’t find a clear explanation.

From what I can tell, it looks like a fillet weld, but that seems incorrect since the joint is a butt joint. Also, I’m unsure what the number “1” refers to in this context.