For starters:

1) You should ask the design engineer for the bolt hole size & pattern.

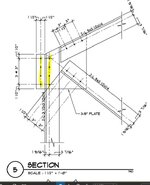

2) Tension controlled (TC) bolts can only be turned via shear wrench on one side. If you have architectural requirements, verify which side the TC bolt head is on. Then verify that the erector can get a shear wrench on the bolt-assembly's nut. A good rule of thumb is 2" from bolt center to face of steel, but 1.75" is acceptable. 1-9/16" shown in the image would cause problems with the angles' outstanding leg (OSL).

3) The 4 bolts highlighted on the left side of the gusset connection are doing absolutely nothing...... except keeping a bolt manufacturer in business.

4) Also note, per AISC, you will need to have stitch plates at 1/3 points along the double angle braces, so the individual angles don't buckle before the brace assembly.