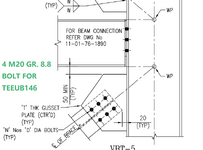

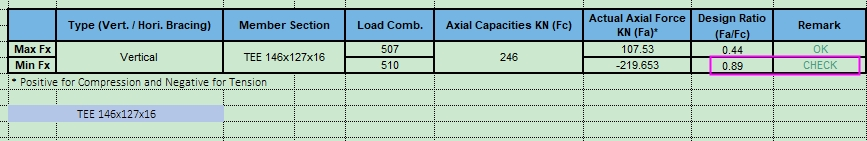

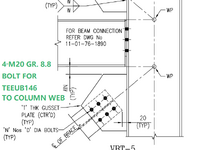

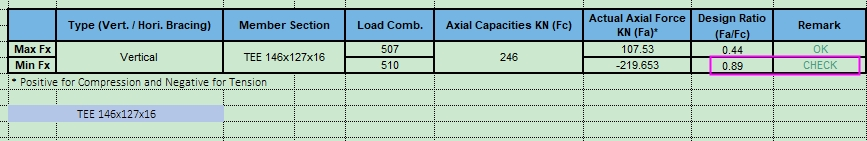

In recent design, ratio for 1 vertical brace connection for TEEUB146 section reached 0.89(<0.85 required, otherwise perform separate check, maximum separate check ratio<1).

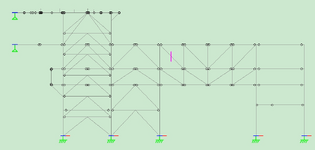

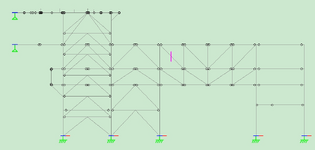

This is a truss member.

The capacity given in standard drawing is 246kN and actual tension is 220kN.

In RAM, the separate check proved the actual ratio is 0.85<1.

Is this case safe or not?

It is not good but true that my ability to calculate steel connection is 0 but only clicking the softwares.

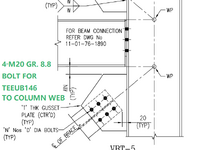

In this case I checked Chinese Code, the shear capacity of 1 bolt differs from location of failure point: shank or thread.

So I sent an email to Vendor of Steel Fabrication, I want to know if the bolt we use is of full length or part thread.

They replied: their product complies with ASTM F3125.

In ASTM F3125, it says

But is their any detailed description about it?

Thank you for reading my thread, and looking forward to your reply.

This is a truss member.

The capacity given in standard drawing is 246kN and actual tension is 220kN.

In RAM, the separate check proved the actual ratio is 0.85<1.

Is this case safe or not?

It is not good but true that my ability to calculate steel connection is 0 but only clicking the softwares.

In this case I checked Chinese Code, the shear capacity of 1 bolt differs from location of failure point: shank or thread.

So I sent an email to Vendor of Steel Fabrication, I want to know if the bolt we use is of full length or part thread.

They replied: their product complies with ASTM F3125.

In ASTM F3125, it says

But is their any detailed description about it?

Thank you for reading my thread, and looking forward to your reply.

Attachments

Last edited: