tmalik3156

Structural

Good day all.

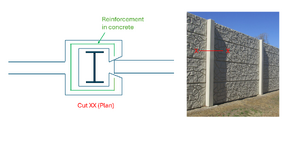

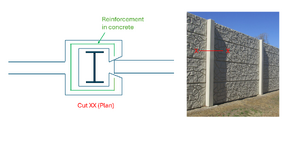

Sketch below is a pilaster of a wall. It's cross section is made of a steel section, and a reinforced concrete cover (C-shaped). The void where the steel is placed is grouted so that there is a composite action between the steel and the concrete.

A pilaster does not carry any significant vertical load, so it's not treated as a column. But it carries a significant horizontal wind load. The steel section is designed to carry that horizontal force alone. However, composite action reduces the horizontal deflection, so the concrete can not be treated merely as a cover.

What minimum reinforcement (shown in green) should we place in the concrete cover? Some people say just use 0.2% for temperature and shrinkage. But I think 0.2% is for slabs, not for a pilaster.

Thank you for your comments / suggestions.

Sketch below is a pilaster of a wall. It's cross section is made of a steel section, and a reinforced concrete cover (C-shaped). The void where the steel is placed is grouted so that there is a composite action between the steel and the concrete.

A pilaster does not carry any significant vertical load, so it's not treated as a column. But it carries a significant horizontal wind load. The steel section is designed to carry that horizontal force alone. However, composite action reduces the horizontal deflection, so the concrete can not be treated merely as a cover.

What minimum reinforcement (shown in green) should we place in the concrete cover? Some people say just use 0.2% for temperature and shrinkage. But I think 0.2% is for slabs, not for a pilaster.

Thank you for your comments / suggestions.