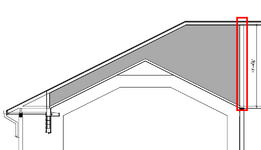

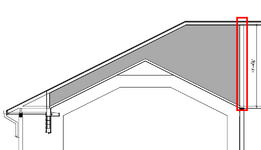

Something like that, yes. With a tall heel the likelihood of imperfections are much higher - from the lumber itself (dimensional lumber isn't looking so hot these days) to tolerances in the construction that could result in some twisting of the cross section.

I disagree. The angular displacement between the chords and the webs will be so small as to create an utterly trivial demand for rotational stability. The extent that the truss will remain plane but be installed out of plumb will create a vastly more significant rotational demand and even that will be miniscule. It's not as though you're going to accept this 13' tall truss being even 2" out of plumb.

This is why the moment arm between points of lateral restraint at the roof diaphragm and top plates doesn't give me ease and I think is rather irrelevant.

See the sketch below demonstrating the relevance of the bracing lever arm. Given that the brace effectiveness will vary in linear proportion to the lever arm, I would argue that there is no single variable that is

more relevant.

I don't think the reason we provide explicit rotational restraint in conventional framing is because the moment arm between points of lateral restraint at the top/bottom is insufficient.

Consider two scenarios with the same end reaction.

1) A 2x10.

2) A 10' tall truss.

Per the sketch below, both setups have the same springs more or less, right? A sheathed diaphragm up top and a nominal shear wall or whatever below. The only difference is the lever arm.

Since the springs are the same, this means that the rotational strength and stiffness provided to the 2x10 is the lesser because of it's reduce lever arm.

The two systems only remain equivalent with respect to rotational stability if the out of plumb-ness of the truss is the same as that of the 2x10. This would cause the P-delta rollover tendency of the truss to grow in the same, linear proportion that the brace effectiveness grows.

But, then, how realistic is

that? Consider:

- a 2x10 at 5% out of plumb will be shifted 0.5" across its depth.

- a 10' truss at 5% out of plumb will be shifted 6" across its depth!

And there in lies the difference between deep and shallow setups. A 1/2" on the 2x10 is conceivable. 6" on the truss is not. Or at the least, at 6" the engineer has recourse to say that the truss is well out of tolerance and, therefore, any associated problems are not the engineer's responsibility.