Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JAE on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Forging Grain Flow Detection 11

- Thread starter gwiz42

- Start date

- Status

- Not open for further replies.

-

1

- #2

You can see grain flow after cold heading before you austenitize. I do not think you can see the flow nondestructively but you can always clean the surface and try a macroetch to see.

Aaron Tanzer

Aaron Tanzer

-

1

- #3

gwiz42-

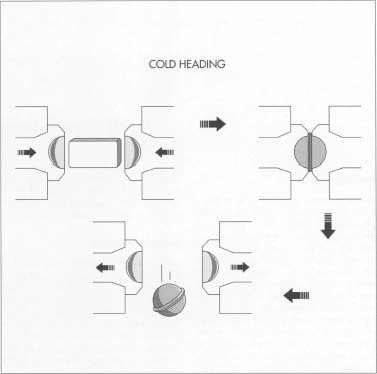

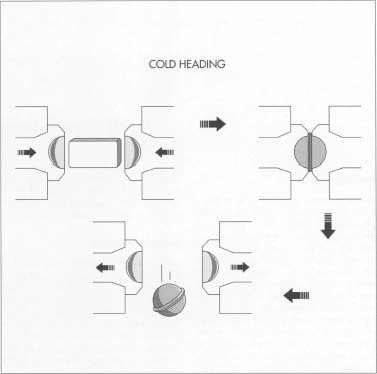

I do not know of any NDI process to determine grain flow direction in your 52100 steel balls. As mrfailure noted, you can etch the ball to enhance the surface grain structure, but that would damage it. Most 52100 steel ball blanks are produced by cold-heading pieces of cut wire.

The wire stock itself is produced by cold drawing and has a very defined grain pattern in the direction the wire is drawn. If you know the grain pattern in the wire stock and how the cut wire pieces feed into the cold-heading dies, then you can probably make a good guess as to what the grain flow pattern will look like in the forged blank. Probably similar to the image below.

The heat treat processes (austenitizing, quench, tempering, etc.) used for through hardening of 52100 steel balls mostly refines the grain microstructure. There is an excellent discussion of the subject provided in sec. 13.5.6 of Essential Concepts of Bearing Technology 5th ed. by Tedric Harris.

Hope that helps.

Terry

I do not know of any NDI process to determine grain flow direction in your 52100 steel balls. As mrfailure noted, you can etch the ball to enhance the surface grain structure, but that would damage it. Most 52100 steel ball blanks are produced by cold-heading pieces of cut wire.

The wire stock itself is produced by cold drawing and has a very defined grain pattern in the direction the wire is drawn. If you know the grain pattern in the wire stock and how the cut wire pieces feed into the cold-heading dies, then you can probably make a good guess as to what the grain flow pattern will look like in the forged blank. Probably similar to the image below.

The heat treat processes (austenitizing, quench, tempering, etc.) used for through hardening of 52100 steel balls mostly refines the grain microstructure. There is an excellent discussion of the subject provided in sec. 13.5.6 of Essential Concepts of Bearing Technology 5th ed. by Tedric Harris.

Hope that helps.

Terry

-

1

- Thread starter

- #4

Flow lines will not be in the finished product. I found they disappeared with refinement after the austenitizing step.

Aaron Tanzer

Aaron Tanzer

I disagree that the flow lines will not be detectable in the finished product. See the attached cross-section of a ball bearing that I etched in a 2% nital solution for 12 seconds. The hardness measured approximately 65 HRC. This image was taken at an original magnification of 50X and the flow lines from cold heading are still clearly visible.

Maui

Maui

-

2

- #7

OK - let's try uploading that image one more time.

Maui

www.EngineeringMetallurgy.com

Maui

www.EngineeringMetallurgy.com

I wonder if the difference is ball size. My balls were about 0.175" diameter and they did not exhibit the strong flow Terry showed after cold heading. The flow that was present disappeared after austenitizing.

Aaron Tanzer

Aaron Tanzer

- Thread starter

- #9

-

4

- #10

This is a very interesting subject. Whether or not an indication of forging grain flow is still visible depends on the specifics of the austenitizing temperature used. What we are seeing in the excellent micrograph provided by Maui (thanks Arthur!) are undissolved primary carbide particles. In high carbon steels like 52100, 1095, etc., the austenitizing temperature is generally low enough that some of the primary carbides remain undissolved, typically < 5% or so. What this means is that these undissolved carbides can be used as an indicator of the forging grain flow.

Notice that this is a microsection with a magnification of ~ 50x. We are looking at the microstructure which is a martensitic matrix with some undissolved carbide particles. The macrosection that Terry provided (equally good T!) is at a much lower magnification, probably only 5-10%, and the microstructure is ferrite + cementite (before quenching and tempering treatment). Macroetching is more aggressive than microetching, because it is performed at elevated temperature 70-80 C for 15-60 minutes using concentrated 50% HCl acid rather than 2% nital (2% concentrated HNO3 + 98% methanol or ethanol) at room temperature for 12 seconds. So, forging grainflow can be indicated using either macroetching or microetching, although the former is the usual method, and is usually done prior to heat treatment. If the steel was a medium carbon grade with say 0.3 to 0.5% C, then there would not be any undissolved carbides, and microetching after heat treating would not reveal the grainflow. Also, if the austenitizing temperature is sufficiently high, all of the carbides will be dissolved, and grainflow will not be visible after heat treating. This may be the case for the balls inspected by mrfailure.

Notice that this is a microsection with a magnification of ~ 50x. We are looking at the microstructure which is a martensitic matrix with some undissolved carbide particles. The macrosection that Terry provided (equally good T!) is at a much lower magnification, probably only 5-10%, and the microstructure is ferrite + cementite (before quenching and tempering treatment). Macroetching is more aggressive than microetching, because it is performed at elevated temperature 70-80 C for 15-60 minutes using concentrated 50% HCl acid rather than 2% nital (2% concentrated HNO3 + 98% methanol or ethanol) at room temperature for 12 seconds. So, forging grainflow can be indicated using either macroetching or microetching, although the former is the usual method, and is usually done prior to heat treatment. If the steel was a medium carbon grade with say 0.3 to 0.5% C, then there would not be any undissolved carbides, and microetching after heat treating would not reveal the grainflow. Also, if the austenitizing temperature is sufficiently high, all of the carbides will be dissolved, and grainflow will not be visible after heat treating. This may be the case for the balls inspected by mrfailure.

-

1

- #11

The original post mentioned 52100 alloy steel and the typical heat treatment used for a rolling element bearing application. I've attached a couple pages from Harris that describe the metallurgy in a 52100 bearing component, and also the relevant sections of AMS2759/2 that describe a typical heat treatment for the same. Maybe this will provide further insight into the subject.

While the topic of discussion is indeed interesting, I would ask gwiz42 why the grain flow in a bearing ball is of particular importance to him/her? In the typical bearing application the ball is loaded only in compression, and since the ball is also unconstrained in rotation about its own center, the radial compression loads are applied at random with respect to any grain flow that might exist in the ball from forging. The predominant stress experienced by a bearing ball is Hertzian contact, and the typical failure mode is a fracture resulting from subsurface shear stresses. The ball's resistance to subsurface shear fractures is greatly improved by having a uniform fine grain microstructure of tempered martensite (as noted by TVP), free from non-metallic inclusions, defects, or retained austenite. But having a specific grain flow orientation would not seem to be of benefit for the fatigue life of a bearing ball.

Maybe gwiz42 can provide more details about his/her particular situation. I don't know a whole lot about metallurgy and it would be great to learn more from others like TVP and Maui.

While the topic of discussion is indeed interesting, I would ask gwiz42 why the grain flow in a bearing ball is of particular importance to him/her? In the typical bearing application the ball is loaded only in compression, and since the ball is also unconstrained in rotation about its own center, the radial compression loads are applied at random with respect to any grain flow that might exist in the ball from forging. The predominant stress experienced by a bearing ball is Hertzian contact, and the typical failure mode is a fracture resulting from subsurface shear stresses. The ball's resistance to subsurface shear fractures is greatly improved by having a uniform fine grain microstructure of tempered martensite (as noted by TVP), free from non-metallic inclusions, defects, or retained austenite. But having a specific grain flow orientation would not seem to be of benefit for the fatigue life of a bearing ball.

Maybe gwiz42 can provide more details about his/her particular situation. I don't know a whole lot about metallurgy and it would be great to learn more from others like TVP and Maui.

You're welcome TVP. Tbuelna, if you're interested in learning more about metallurgy I'd suggest looking through a copy of my book:

It's been purchased by over 450 college and university libraries throughout the world so far. If one of them is near you, you may be able to visit their engineering/physics library to read it for free. You can see a listing of the schools that have purchased it through this link:

Maui

It's been purchased by over 450 college and university libraries throughout the world so far. If one of them is near you, you may be able to visit their engineering/physics library to read it for free. You can see a listing of the schools that have purchased it through this link:

Maui

- Thread starter

- #13

I am using 2 & 2.5 inch 52100 balls. At this size, it's at the border of cold forge/hot forge and typically requires at least two hits. Purchasing is looking for cheap (don't get me started on this...) so we are looking at cheap balls from Asia and don't have any information on them. Experience has shown some cold forged balls can rotate between hits, effectively resulting in four poles. NACA performed a pretty cool study of failures areas on bearing balls that shows pole areas are the most likely to fail.

Link

So, I am trying to find a NDT method that might be able to detect this. Although, I'm not sure if its possible, and hopefully I'll win my battle with the purchasing folks to go with a reputable ball maker...

Link

So, I am trying to find a NDT method that might be able to detect this. Although, I'm not sure if its possible, and hopefully I'll win my battle with the purchasing folks to go with a reputable ball maker...

-

1

- #14

You should really care more about the finished product. Look at ASTM A892, which provides microstructural ratings that you can specify for purchase for these balls. You also should also make sure they conform to 52100 per ASTM A295.

Aaron Tanzer

Aaron Tanzer

gwiz42- Thanks for the additional information. If you are constrained by cost, then performing a surface etch on each forging to verify grain orientation is obviously not a practical solution. If you feel that achieving a specific grain orientation in your forged blanks is a critical factor in the performance of your parts, then it would be best to work with your suppliers to develop a controlled process spec that will be a requirement of your purchase order. The process spec would require your supplier to perform certain QA tasks that demonstrate their process produces conforming products, including producing parts with consistent grain orientation. The number of samples subject to full (destructive) inspection is gradually reduced over time as you gain confidence in the supplier's process control. Eventually the full inspection would only be required once per lot.

I quickly glanced through that NACA paper you linked. One thing that caught my eye was the extremely high hertzian contact stress level (>650ksi) used in the tests. Even a high quality bearing ball intended for average service life would never be designed for mean hertzian contact stress levels much above 350ksi, and the same bearing ball produced using commercial quality materials and processes would be designed for mean hertzian contact stress levels below about 250ksi. While that paper documents some excellent basic research work, it was published in 1957. One thing regarding rolling element bearing fatigue life that has changed significantly since then is the huge improvements in metallurgy. By switching from an air melt (52100) steel to a double vacuum melt (CEVM E52100) steel, you can easily achieve a 200% to 300% increase in predicted fatigue life. I agree with mrfailure's advice for ASTM A892, but for the highest quality steel I would recommend ASTM A535 or AMS 6444.

Lastly, since you noted that the size of your ball blanks required hot forging, I would suggest that you specify a minimum stock removal of 1/8" from the forged surface. The outer surface of hot forged materials is contaminated and metallurgically unsound.

Good luck.

Terry

I quickly glanced through that NACA paper you linked. One thing that caught my eye was the extremely high hertzian contact stress level (>650ksi) used in the tests. Even a high quality bearing ball intended for average service life would never be designed for mean hertzian contact stress levels much above 350ksi, and the same bearing ball produced using commercial quality materials and processes would be designed for mean hertzian contact stress levels below about 250ksi. While that paper documents some excellent basic research work, it was published in 1957. One thing regarding rolling element bearing fatigue life that has changed significantly since then is the huge improvements in metallurgy. By switching from an air melt (52100) steel to a double vacuum melt (CEVM E52100) steel, you can easily achieve a 200% to 300% increase in predicted fatigue life. I agree with mrfailure's advice for ASTM A892, but for the highest quality steel I would recommend ASTM A535 or AMS 6444.

Lastly, since you noted that the size of your ball blanks required hot forging, I would suggest that you specify a minimum stock removal of 1/8" from the forged surface. The outer surface of hot forged materials is contaminated and metallurgically unsound.

Good luck.

Terry

Note that ASTM A535 was withdrawn in 1998 and is defunct.

Regarding AMS 6444 - you need to look at it and compare with A295 to determine quality level needed. For example A295 has cleaner microcleanliness specified for type C (silicate) and D (oxide)inclusions but 6444 is tighter with A (sulfides) and B (aluminides). 6444 is very good at specifying quality of material used in fabrication of the balls.

Finally, note that international supply houses may have different levels of quality for 52100 balls. Make sure you select the quality level you require, and not necessarily the cheapest balls that they quote to you. Yes, quality does cost money!

Aaron Tanzer

Regarding AMS 6444 - you need to look at it and compare with A295 to determine quality level needed. For example A295 has cleaner microcleanliness specified for type C (silicate) and D (oxide)inclusions but 6444 is tighter with A (sulfides) and B (aluminides). 6444 is very good at specifying quality of material used in fabrication of the balls.

Finally, note that international supply houses may have different levels of quality for 52100 balls. Make sure you select the quality level you require, and not necessarily the cheapest balls that they quote to you. Yes, quality does cost money!

Aaron Tanzer

- Thread starter

- #17

FWIW, ASTM F2215-08 (Standard Specification for Balls) is what I generally call out along with specific material, but there are still other issues I have to spec out above and beyond this. And, giving any spec requirement overseas doesn't mean anything. Those guys bet you won't check the quality.

And Terry, you are right about the feasibility of etching, that's why I'm hoping somebody knows of a NDT method that maybe able to detect grain flow (although all signs are pointing to 'no').

And Terry, you are right about the feasibility of etching, that's why I'm hoping somebody knows of a NDT method that maybe able to detect grain flow (although all signs are pointing to 'no').

- Status

- Not open for further replies.

Similar threads

- Locked

- Question

- Replies

- 11

- Views

- 801

- Replies

- 12

- Views

- 835

- Locked

- Question

- Replies

- 0

- Views

- 422

- Locked

- Question

- Replies

- 20

- Views

- 2K

- Locked

- Question

- Replies

- 2

- Views

- 667