@

TGS4,thanks for reply.

my two cents:

1. Vessels to be PWHT(For CS)

i think it's not mandated in both Div.1&Div.2 of Section VIII, despite of that, i think the reduced residual stress and improved toughness of material, as a result of PWHT (for CS), could benefit the increase of fatigue life. i don't quite understand the rationale underneath it, i guess the stress amplitude of a location in interest in a PWHTed vessel would be significantly decreased than that in the vessel kept being as-welded, under the same operating condition.

2. All welds be full penetration

not mandatory.

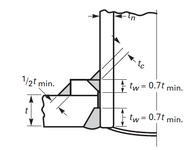

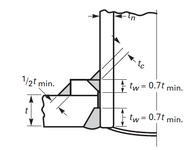

i think partial penetration creates sharp corners/edges, especially in the gaps (e.g. the nozzle neck and shell) where could not be visually seen by eyes, thus hard to achieve a smooth contour of weld. it's these locations hidden somewhere that are prone to crack under cyclic loads.

it's a recommended good practice.

Not mandatory.

similar logic as 2. the construction not integral can't avoid sharp corners/edges (e.g. between the repad and shell) . it's these locations where are prone to crack under cyclic loads.

it's a recommended good practice.

Not mandatory,

but recommended.

Slip-on is not integral construction.

Not mandatory.

typically the wear plate attached to head shall be used for leg support, which isn't a integral construction. Maybe there is only one solution, SKIRT, which could achieve a full penetration between support and shell. it's not practical to use a skirt on those common vertical vessels except for tall towers.

i think the factor could be disregarded if not for towers.

6. Avoid peaking at Category A joints

Not mandatory.

para. 5.5.1.7 in Div.2 states: " If a fatigue analysis is required, the effects of joint alignment (see 6.1.6.1) and

weld peaking (see 6.1.6.3) in

shells and heads shall be considered in the determination of the applicable stresses."

the clause seems implying that the weld peaking shall be considered in fatigue analysis rather than be avoided. i look through the VIII-2 and couldn't figure out how to consider the weld peaking in analysis. maybe just dictate a max. limit for the peaking in fabrication drawing, similar as the misalignment of joint, and perform the FEA as usual. when it comes to reality, but how to determine the limit? it seems tricky.

in my experience, no engineer considers the peaking limit of weld either in the fabrication drawing or in the FEA report. it puzzles me.

above are my thoughts on these factor, please comment.

actually, my colleague also advised some other factor for cyclic service, such as main weld joint ground flush, material to be normalized, material to be fine grained, which i am clear about, have no confusion.

Any reply appreciated, thanks.