AMINATAISSA

Industrial

Dear All,

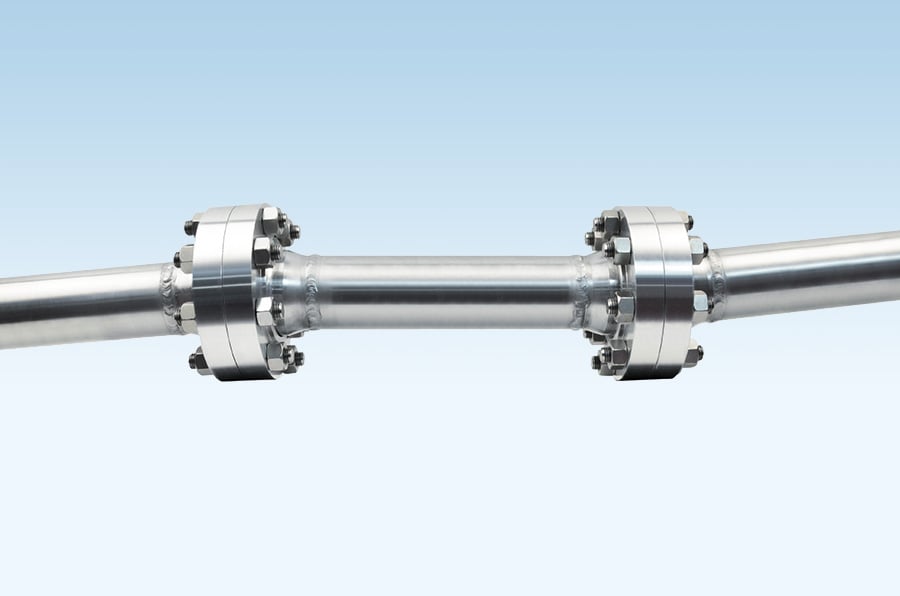

We're reaching out to the community for expertise in fabricating spherical socket joints for large-diameter DN2500mm water pipelines. We plan to utilize steel sheets for the pipe itself (we are a construction society) but are lacking a specific methods statement outlining the fabrication process for the joints.

Any insights or experience from someone who has tackled a similar challenge would be greatly appreciated. We're open to various approaches and materials for achieving a safe, durable, and watertight connection.

Your assistance would be incredibly valuable in advancing this project. We are also happy to share any information or challenges we encounter in return.

Thank you for your time and consideration.

We're reaching out to the community for expertise in fabricating spherical socket joints for large-diameter DN2500mm water pipelines. We plan to utilize steel sheets for the pipe itself (we are a construction society) but are lacking a specific methods statement outlining the fabrication process for the joints.

Any insights or experience from someone who has tackled a similar challenge would be greatly appreciated. We're open to various approaches and materials for achieving a safe, durable, and watertight connection.

Your assistance would be incredibly valuable in advancing this project. We are also happy to share any information or challenges we encounter in return.

Thank you for your time and consideration.