I have heard about O-Ring leaks of Jamco toilet fixtures on 787s, but this is first I have seen/heard, or remember seeing/hearing, about galvanic corrosion of bathroom fixtures. This could potentially cause a sudden increase to the 8 ounces/hour rate of just O-ring leaks....... galvanic corrosion issues has to be handled by systems requirements and systems integration, and quality control.

"Boeing 787 Lavatory Issues"

"

Boeing 787 aircraft are facing a safety concern with their lavatories, according to a recent FAA proposal. The agency has identified corrosion problems on lower fitting assemblies of

Jamco family 95/96 lavatories caused by

galvanic interaction between aluminum and carbon fiber components in the wet lavatory environment.

This corrosion could cause lavatories to break free during high g-force events, potentially

injuring passengers and

crew or blocking emergency exits.

The proposed Airworthiness Directive (AD) would require airlines to inspect the affected components for corrosion, record findings, make necessary repairs, and update maintenance programs to include regular inspections.

The directive would affect approximately

159 U.S.-registered Boeing 787-8, 787-9, and 787-10 airplanes."

The Federal Aviation Administration (FAA) has proposed a new Airworthiness Directive (AD) affecting Boeing 787-8, 787-9, and 787-10 airplanes. This action comes after reports of corrosion on lower fitting assemblies of certain lavatories.

aviationa2z.com

"Background"

"The FAA has received reports indicating corrosion on one or more of the eight lower fitting assemblies and adjacent lavatory components on the Jamco family 95/96 lavatories caused by the galvanic interaction of aluminum and carbon fiber as a result of the wet environment at the lavatory. This condition, if not addressed, could cause the lavatories to break free from the lower mounts during an event with high g-forces, resulting in potential serious injury to passengers and crew or a displaced lavatory blockage that prevents egress through the aisle and exits."

www.federalregister.gov

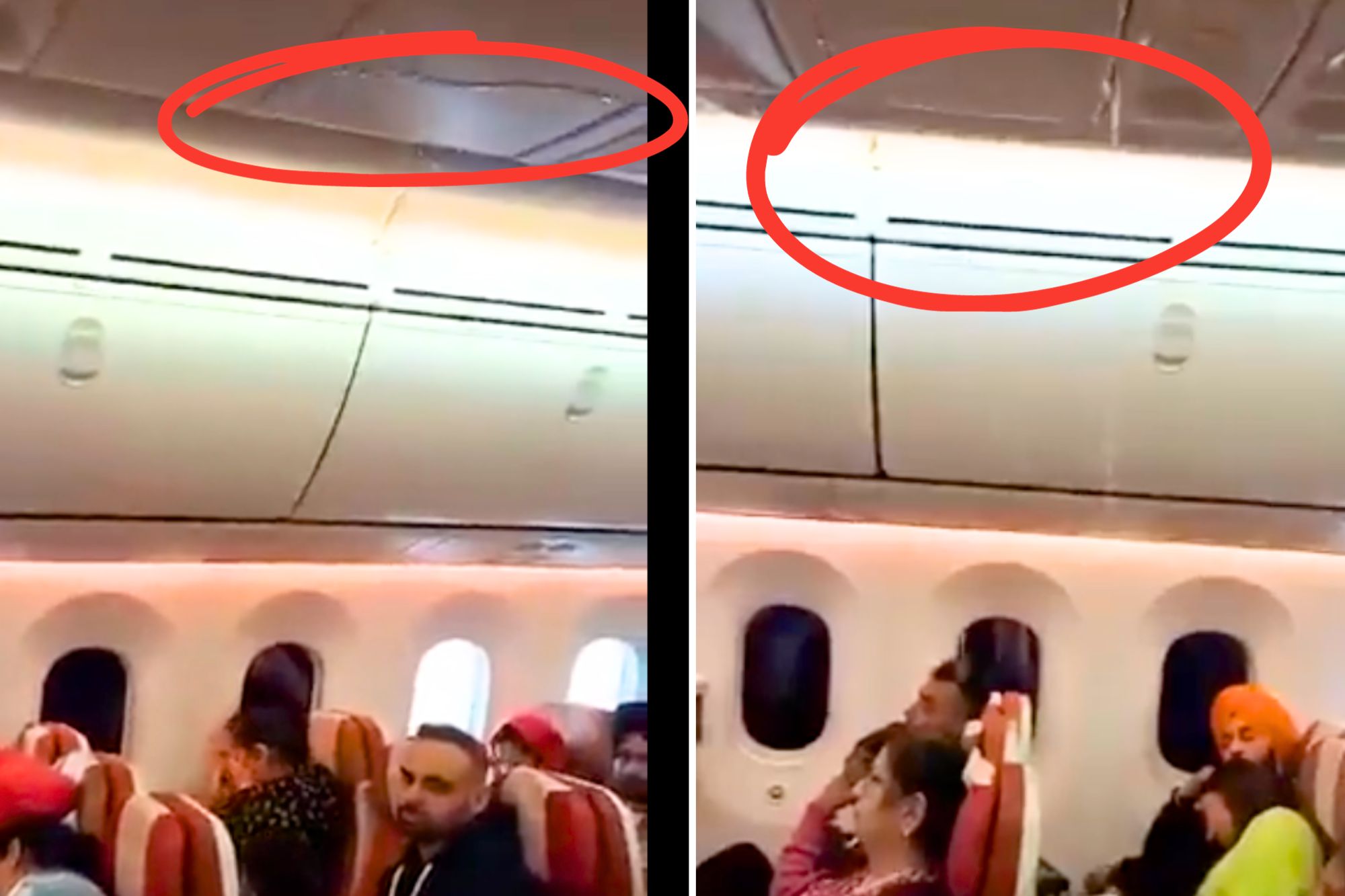

NOT TO PLACE all blame on Boeing as aircraft maintenance after production is key part of air safety. Here is link with video showing what appears to be leaking condensation from the air conditioning system. Likely due to lack of maintenance.

Video footage of an Air India flight from Gatwick to Amritsar has gone viral after water leaked into the cabin from overhead bins.

www.aerotime.aero

www.theguardian.com

www.theguardian.com