jochav52802

Structural

Good Day!

Does ACI specify the minimum edge distance required beyond the critical perimeter for that perimeter to be effective in two-way shear?

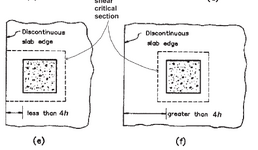

All I can find is Section-22.6.4.3, where they say that openings located less than 4h from the column face eliminate the effectiveness of the associated critical perimeter, but am unsure as to whether this is to be used for identifying general free edges as well.

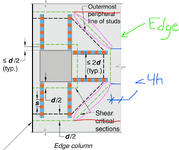

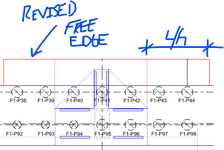

Wondering if this 4h also applies to the outermost critical section when punching shear reinforcement is required. I don't see the CRSI Design Guide for Pile Caps performing any edge distance check on the critical perimeter, so wondering what is best practice here. Intuitively and practically speaking, at some point, when there's very little edge distance, I would think the adjacent critical perimeter would not be effective.

Many thanks in advance for your wisdom here!

Does ACI specify the minimum edge distance required beyond the critical perimeter for that perimeter to be effective in two-way shear?

All I can find is Section-22.6.4.3, where they say that openings located less than 4h from the column face eliminate the effectiveness of the associated critical perimeter, but am unsure as to whether this is to be used for identifying general free edges as well.

Wondering if this 4h also applies to the outermost critical section when punching shear reinforcement is required. I don't see the CRSI Design Guide for Pile Caps performing any edge distance check on the critical perimeter, so wondering what is best practice here. Intuitively and practically speaking, at some point, when there's very little edge distance, I would think the adjacent critical perimeter would not be effective.

Many thanks in advance for your wisdom here!