I am looking for someone that could reverse engineer some structural drawings for me.

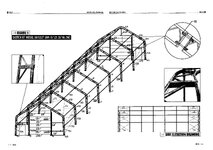

I bought a fabric shelter from a person off Facebook Market place but it didn't come with engineering diagrams or specs. In order to get a building permit the township is asking for drawings with an engineer's stamp so that they know it meets Ontario building code. Is there an engineer here that could reverse engineer the drawings for me, for a fee obviously and with a lot of support from me getting all the dimensions and details? The original manufacturer seems to have gone out of business so I am unable to get anything from them. Attached is a page from the assembly manual with as much detail as they provide.

TMG Industrial sell a similar building. Theirs uses 2" round 15 gauge tubing and they claim 60 lbs/sq. ft snow load. This one that I have uses 2 5/8" x 1 5/8" oval tubing and is 13 gauge so I am confident it will meet the code. I just need to prove it to the building department.

I bought a fabric shelter from a person off Facebook Market place but it didn't come with engineering diagrams or specs. In order to get a building permit the township is asking for drawings with an engineer's stamp so that they know it meets Ontario building code. Is there an engineer here that could reverse engineer the drawings for me, for a fee obviously and with a lot of support from me getting all the dimensions and details? The original manufacturer seems to have gone out of business so I am unable to get anything from them. Attached is a page from the assembly manual with as much detail as they provide.

TMG Industrial sell a similar building. Theirs uses 2" round 15 gauge tubing and they claim 60 lbs/sq. ft snow load. This one that I have uses 2 5/8" x 1 5/8" oval tubing and is 13 gauge so I am confident it will meet the code. I just need to prove it to the building department.