IcarusAero223

Aerospace

- Mar 10, 2024

- 12

Hello everyone!

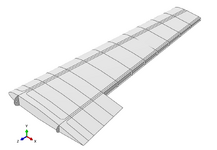

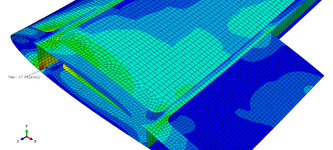

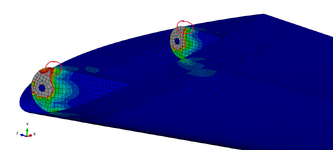

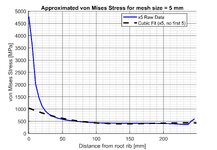

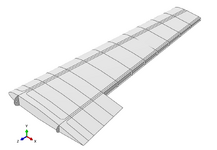

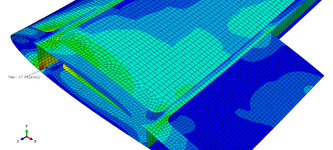

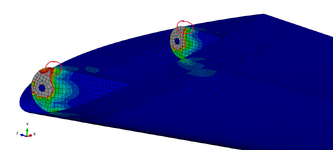

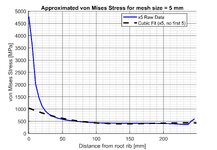

I'm modelling a composite wing and am exhibiting a mesh singularity at the spar web/cap connection.

Solutions I've tried:

And as you can see none of it really worked so I decided to come here and see if anyone has an answer to this little problem I have.

I'm assuming the fix might not be the modelling approach but rather geometry modification and for that I have no more ideas unfortunately.

Any help is appreciated!![[bigears] [bigears] [bigears]](/data/assets/smilies/bigears.gif)

I'm modelling a composite wing and am exhibiting a mesh singularity at the spar web/cap connection.

Solutions I've tried:

- Modelling softer boundary conditions through springs

- Reducing the stiffness of the spar webs

- Pulling out spar web surfaces and modelling BC's through idealized bolted contact

And as you can see none of it really worked so I decided to come here and see if anyone has an answer to this little problem I have.

I'm assuming the fix might not be the modelling approach but rather geometry modification and for that I have no more ideas unfortunately.

Any help is appreciated!

![[bigears] [bigears] [bigears]](/data/assets/smilies/bigears.gif)