MAEngr

Structural

- Jul 28, 2021

- 20

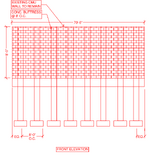

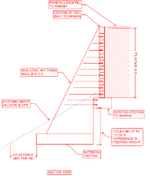

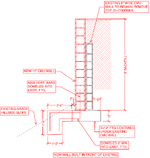

I am evaluating an exterior retaining wall that a contractor built to prescriptive codes. They came back after inspection and added two feet of additional retaining height which means insufficient rebar in the wall and inadequate footing sizes. The wall is starting to bow in the middle. The owner would like to not demo and rebuild the wall. My thoughts on repair would be to add a haunched wall butted against the existing wall with dowels and to add additional concrete/rebar to the footing. Is this the approach you all recommend? They would also be open to a buttress wall in the middle on the exposed side since that side is downhill and not visible. I don’t like this option as much.