Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations TugboatEng on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wear in abaqus

- Thread starter Iman@123

- Start date

- Thread starter

- #3

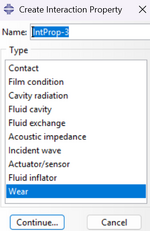

I did not edit the keyword; that's why I don't know what is the problem.Check the documentation chapter Interactions --> Contact Property Models --> Mechanical Contact Properties --> Contact Wear. You can have one rigid body.

Regarding the error, did you use a comma instead of a dot as a decimal separator ?

but in the .inp file, the error came after these:

***NOTE: OUTPUT REQUEST DAMAGEC IS NOT AVAILABLE FOR THE MATERIAL L80

***NOTE: OUTPUT REQUEST DAMAGEC IS NOT AVAILABLE FOR THE MATERIAL S7

***NOTE: OUTPUT REQUEST DMICRT IS NOT AVAILABLE FOR THE MATERIAL S7

***NOTE: OUTPUT REQUEST SDEG IS NOT AVAILABLE FOR THE MATERIAL S7*surface, type=ELEMENT, name=ASSEMBLY_SURF-1*surface, type=ELEMENT, name=ASSEMBLY_SURF-2*surface, type=ELEMENT, name=ASSEMBLY_TJ*surface, type=ELEMENT, name=ASSEMBLY__PICKEDSURF12*surface, type=NODE, name=ASSEMBLY_PART-3-1_CASINGSET_CNS_*surfaceinteraction, name=CONTACT*friction*surfacebehavior, pressure-overclosure=HARD*surfaceproperty, name=WEAR*wearsurfaceproperties, friccoefdependent=YES, unitlesswearcoef=NO

***ERROR: THESE CHARACTERS DO NOT CONVERT TO FLOATING POINT VALUELINE IMAGE: 1.248e-08, , 1e-09, , ***boundary*boundary, type=VELOCITY*step, name=Step-1, nlgeom=YES*dynamic, explicit*boundary, op=NEW

***WARNING: THE OPTION *BOUNDARY,TYPE=DISPLACEMENT HAS BEEN USED; CHECK STATUSFILE BETWEEN STEPS FOR WARNINGS ON ANY JUMPS PRESCRIBED ACROSS THESTEPS IN DISPLACEMENT VALUES OF TRANSLATIONAL DOF. FOR ROTATIONALDOF MAKE SURE THAT THERE ARE NO SUCH JUMPS. ALL JUMPS INDISPLACEMENTS ACROSS STEPS ARE IGNORED*boundary, op=NEW, type=VELOCITY*cload, amplitude=AMP-1*contactpair, interaction=CONTACT, mechanicalconstraint=KINEMATIC, cpset=INT-3*endstep

- Thread starter

- #5

Can you share the .inp file (you can reduce the model to the minimum necessary to reproduce the issue) ?

PROCESSING PART, INSTANCE, AND ASSEMBLY INFORMATION

*******************************************************

END PROCESSING PART, INSTANCE, AND ASSEMBLY INFORMATION

***********************************************************

OPTIONS BEING PROCESSED

***************************

*Element, type=C3D8R

*Elset, elset=ASSEMBLY_PART-3-1_SET-2

*Element, type=C3D8R

*Elset, elset=ASSEMBLY_PART-4-1_SET-2

*Elset, elset=ASSEMBLY_B_SET-9

*Elset, elset=ASSEMBLY_CASCONT

*Elset, elset=ASSEMBLY_LOWERCAS

*Elset, elset=ASSEMBLY__PICKEDSET14

*Elset, elset=ASSEMBLY__SURF-1_S3

*Elset, elset=ASSEMBLY__SURF-1_S4

*Elset, elset=ASSEMBLY__SURF-1_S5

*Elset, elset=ASSEMBLY__SURF-1_S6

*Elset, elset=ASSEMBLY__SURF-2_S3

*Elset, elset=ASSEMBLY__SURF-2_S4

*Elset, elset=ASSEMBLY__SURF-2_S5

*Elset, elset=ASSEMBLY__SURF-2_S6

*Elset, elset=ASSEMBLY__TJ_S3

*Elset, elset=ASSEMBLY__TJ_S4

*Elset, elset=ASSEMBLY__TJ_S5

*Elset, elset=ASSEMBLY__TJ_S6

*Elset, elset=ASSEMBLY___PICKEDSURF12_S1

*Elset, elset=ASSEMBLY___PICKEDSURF12_S2

*Elset, elset=ASSEMBLY___PICKEDSURF12_S3

*Elset, elset=ASSEMBLY___PICKEDSURF12_S4

*Elset, elset=ASSEMBLY___PICKEDSURF12_S5

*Elset, elset=ASSEMBLY___PICKEDSURF12_S6

*heading

*material, name=L80

*damageinitiation, criterion=DUCTILE

*damageevolution, type=DISPLACEMENT

*density

*elastic

*plastic

*material, name=S7

*density

*elastic

*solidsection, elset=ASSEMBLY_PART-3-1_SET-2, controls=EC-1, material=L80

*solidsection, elset=ASSEMBLY_PART-4-1_SET-2, controls=EC-2, material=S7

*sectioncontrols, name=EC-1, elementdeletion=YES

*sectioncontrols, name=EC-2, elementdeletion=NO

*solidsection, elset=ASSEMBLY_PART-3-1_SET-2, controls=EC-1, material=L80

*solidsection, elset=ASSEMBLY_PART-4-1_SET-2, controls=EC-2, material=S7

*rigidbody, refnode=ASSEMBLY__PICKEDSET58, elset=ASSEMBLY_B_SET-9

*rigidbody, refnode=ASSEMBLY__PICKEDSET58, elset=ASSEMBLY_B_SET-9

*rigidbody, refnode=ASSEMBLY__PICKEDSET58, elset=ASSEMBLY_B_SET-9

*rigidbody, refnode=ASSEMBLY__PICKEDSET58, elset=ASSEMBLY_B_SET-9

*surface, type=ELEMENT, name=ASSEMBLY_SURF-1

*surface, type=ELEMENT, name=ASSEMBLY_SURF-2

*surface, type=ELEMENT, name=ASSEMBLY_TJ

*surface, type=ELEMENT, name=ASSEMBLY__PICKEDSURF12

*surface, type=NODE, name=ASSEMBLY_PART-3-1_CASINGSET_CNS_

*surface, type=ELEMENT, name=ASSEMBLY_SURF-1

*surface, type=ELEMENT, name=ASSEMBLY_SURF-2

*surface, type=ELEMENT, name=ASSEMBLY_TJ

*surface, type=ELEMENT, name=ASSEMBLY__PICKEDSURF12

*surface, type=NODE, name=ASSEMBLY_PART-3-1_CASINGSET_CNS_

*rigidbody, refnode=ASSEMBLY__PICKEDSET58, elset=ASSEMBLY_B_SET-9

*surfaceinteraction, name=CONTACT

*friction

*surfaceproperty, name=WEAR

*wearsurfaceproperties, friccoefdependent=YES, unitlesswearcoef=NO

***ERROR: THESE CHARACTERS DO NOT CONVERT TO FLOATING POINT VALUE

LINE IMAGE: 1.248e-08, , , , **

***NOTE: DUE TO AN INPUT ERROR THE ANALYSIS PRE-PROCESSOR HAS BEEN UNABLE TO

INTERPRET SOME DATA. SUBSEQUENT ERRORS MAY BE CAUSED BY THIS OMISSION

*rigidbody, refnode=ASSEMBLY__PICKEDSET58, elset=ASSEMBLY_B_SET-9

*rigidbody, refnode=ASSEMBLY__PICKEDSET58, elset=ASSEMBLY_B_SET-9

*boundary

*boundary, type=VELOCITY

*boundary, op=NEW

*boundary, op=NEW, type=VELOCITY

*solidsection, elset=ASSEMBLY_PART-3-1_SET-2, controls=EC-1, material=L80

*solidsection, elset=ASSEMBLY_PART-4-1_SET-2, controls=EC-2, material=S7

*rigidbody, refnode=ASSEMBLY__PICKEDSET58, elset=ASSEMBLY_B_SET-9

*friction

*elementoutput, directions=YES

*output, field

*output, history, variable=PRESELECT

*step, name=Step-1, nlgeom=YES

*step, name=Step-1, nlgeom=YES

*dynamic, explicit

*boundary, op=NEW

*boundary, op=NEW, type=VELOCITY

*adaptivemeshcontrols, name=ADA-1

*output, field

*nodeoutput

*elementoutput, directions=YES

*contactoutput, variable=PRESELECT

*output, history, variable=PRESELECT

*endstep

***WARNING: INTEGRATION AND SECTION POINT OUTPUT VARIABLES WILL NOT BE OUTPUT

FOR DEFORMABLE ELEMENTS THAT ARE DECLARED AS RIGID USING THE

*RIGID BODY OPTION

***NOTE: OUTPUT REQUEST DAMAGEC IS NOT AVAILABLE FOR THE MATERIAL L80

*surface, type=ELEMENT, name=ASSEMBLY_SURF-1

*surface, type=ELEMENT, name=ASSEMBLY_SURF-2

*surface, type=ELEMENT, name=ASSEMBLY_TJ

*surface, type=ELEMENT, name=ASSEMBLY__PICKEDSURF12

*surface, type=NODE, name=ASSEMBLY_PART-3-1_CASINGSET_CNS_

*surfaceinteraction, name=CONTACT

*friction

*surfacebehavior, pressure-overclosure=HARD

*surfaceproperty, name=WEAR

*wearsurfaceproperties, friccoefdependent=YES, unitlesswearcoef=NO

***ERROR: THESE CHARACTERS DO NOT CONVERT TO FLOATING POINT VALUE

LINE IMAGE: 1.248e-08, , , , **

*boundary

*boundary, type=VELOCITY

*step, name=Step-1, nlgeom=YES

*dynamic, explicit

*boundary, op=NEW

***WARNING: THE OPTION *BOUNDARY,TYPE=DISPLACEMENT HAS BEEN USED; CHECK STATUS

FILE BETWEEN STEPS FOR WARNINGS ON ANY JUMPS PRESCRIBED ACROSS THE

STEPS IN DISPLACEMENT VALUES OF TRANSLATIONAL DOF. FOR ROTATIONAL

DOF MAKE SURE THAT THERE ARE NO SUCH JUMPS. ALL JUMPS IN

DISPLACEMENTS ACROSS STEPS ARE IGNORED

*boundary, op=NEW, type=VELOCITY

*cload, amplitude=AMP-1

*contactpair, interaction=CONTACT, mechanicalconstraint=KINEMATIC, cpset=INT-3

*endstep

P R O B L E M S I Z E

NUMBER OF ELEMENTS IS 1665

NUMBER OF NODES IS 3821

NUMBER OF NODES DEFINED BY THE USER 3821

TOTAL NUMBER OF VARIABLES IN THE MODEL 11466

(DEGREES OF FREEDOM PLUS MAX NO. OF ANY LAGRANGE MULTIPLIER

VARIABLES. INCLUDE *PRINT,SOLVE=YES TO GET THE ACTUAL NUMBER.)

THE PROGRAM HAS DISCOVERED 2 FATAL ERRORS

** EXECUTION IS TERMINATED **

END OF USER INPUT PROCESSING

JOB TIME SUMMARY

USER TIME (SEC) = 0.80

SYSTEM TIME (SEC) = 0.50

TOTAL CPU TIME (SEC) = 1.3

WALLCLOCK TIME (SEC) = 1

Last edited:

I meant the .inp file (not .dat) but it doesn't have to be the whole file. You can attach some small segment of it since the problem is with this part:

Maybe there's some unnecessary space or something like that.

But if it looks like this in the input file then it should be ok:*wearsurfaceproperties, friccoefdependent=YES, unitlesswearcoef=NO

***ERROR: THESE CHARACTERS DO NOT CONVERT TO FLOATING POINT VALUE

LINE IMAGE: 1.248e-08, , , , **

Code:

*wearsurfaceproperties, friccoefdependent=YES, unitlesswearcoef=NO

1.248e-08, , , ,Maybe there's some unnecessary space or something like that.

- Thread starter

- #7

Similar threads

- Replies

- 1

- Views

- 3K

- Replies

- 4

- Views

- 751

- Replies

- 2

- Views

- 401

- Question

- Replies

- 1

- Views

- 9K