Hello,

I would need some help regarding butt weld specifications.

Could it be Butt weld regardless the angle of the pipe end. I mean, if no specification further than BW are indicated, could the pipe or accessory be supplied either with 37.5º or 0.5º?

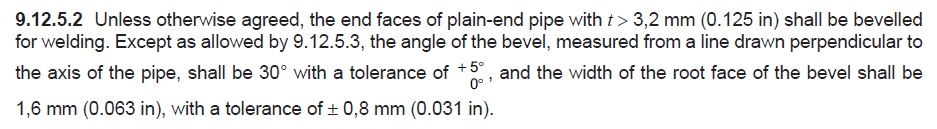

I can't find the specifications in the ASME

Thanks and regards

I would need some help regarding butt weld specifications.

Could it be Butt weld regardless the angle of the pipe end. I mean, if no specification further than BW are indicated, could the pipe or accessory be supplied either with 37.5º or 0.5º?

I can't find the specifications in the ASME

Thanks and regards