I'm looking at using the nice aluminum front control arms from an NC or ND Miata for my reverse trike.

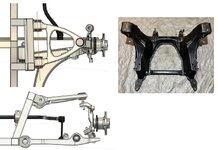

I'm not sure if they've kept geometry similar to the NB Miata front suspension pictured below (the only Miata suspension 3D model I could find), but in any case the UCA's axes are tilted inward by about 2 1/2 deg.

I'm sure the Mazda engineers had a good reason for doing this, but what is it?

The arms are also tilted about the transverse axis about 4 1/2 deg for anti-dive, which besides doing that also seems nice in that it counteracts loss of caster from the remaining nose dive, But the semi-trailing component does the opposite.

Besides that, is a paltry 2 1/2 deg worth the extra frame construction complexity?

I'm not sure if they've kept geometry similar to the NB Miata front suspension pictured below (the only Miata suspension 3D model I could find), but in any case the UCA's axes are tilted inward by about 2 1/2 deg.

I'm sure the Mazda engineers had a good reason for doing this, but what is it?

The arms are also tilted about the transverse axis about 4 1/2 deg for anti-dive, which besides doing that also seems nice in that it counteracts loss of caster from the remaining nose dive, But the semi-trailing component does the opposite.

Besides that, is a paltry 2 1/2 deg worth the extra frame construction complexity?