Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations TugboatEng on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welding joint

- Thread starter salgu

- Start date

- Status

- Not open for further replies.

Dhurjati Sen

Materials

If you want a quick job, start with two welders welding from diametrically opposite side.

DHURJATI SEN

DHURJATI SEN

Correction: This uses downhill welding rates. Thickness requires uphill rates. See later posts.

5.67 man_hrs

From

34mm/3.5 mm/pass = 10 passes

Maybe 3mm-5mm/pass

Circumference

18" x 3.14 = 56 in/pass

560 inches weld / (120 in of weld per hr) = 4.67 hrs

Usually 100 to 140in weld/hr

20% other work = 1 hr

Change your variables to suit your weld procedure and productivity info.

5.67 man_hrs

From

34mm/3.5 mm/pass = 10 passes

Maybe 3mm-5mm/pass

Circumference

18" x 3.14 = 56 in/pass

560 inches weld / (120 in of weld per hr) = 4.67 hrs

Usually 100 to 140in weld/hr

20% other work = 1 hr

Change your variables to suit your weld procedure and productivity info.

When you're looking at 1500 km of pipeline (120,000 joints), you gotta know how to estimate welding time. Its obvious why we like high strength, [pre][/pre]thin wall pipe. Welding rate drives pipeline construction time.

Every welder on the internet says that they can do 80in/hr with one hand tied behind their back.

100 in/hr for thin wall pipe, 140 for thick wall has been stated in "Pipeline Rules of Thumb" E.W. McAllister since the FIRST Edition 1978

Every welder on the internet says that they can do 80in/hr with one hand tied behind their back.

100 in/hr for thin wall pipe, 140 for thick wall has been stated in "Pipeline Rules of Thumb" E.W. McAllister since the FIRST Edition 1978

I used an average 40ft "double joint" length and rounded up a bit.

Pass thickness varies by rod diameter, weld technique and groove angle(s).

Considering XL83NL question, I might have been too fast choosing 3.5mm, being too liberal for the bevel geometry for this rather thick pipe. This weld will be pretty wide at the outside surface. It should have a compound bevel, reducing the OD width, but avg pass thickness may turn out to be even less. 3.5mm works OK for estimating pipelines, usually having thinner walls, in the 5-10mm range.

So let's take a closer look.

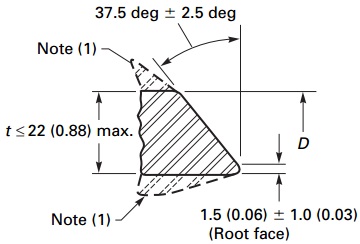

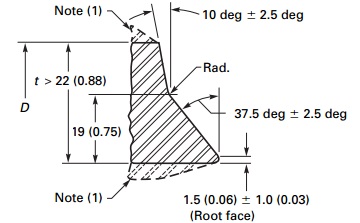

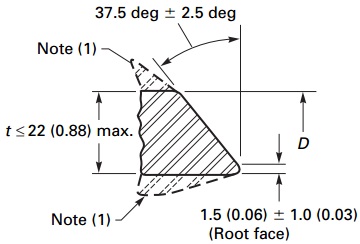

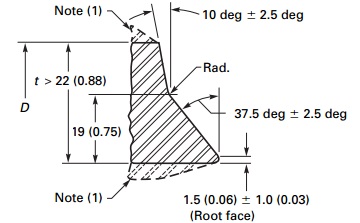

Adjusting for weld groove angle on each pipe end, typ plain 30° bevels, or compound bevels,

This "single bevel" chart says that my number of passes estimate of 10, only works for 2x30° bevels when wall thickness is around 0.5" (12mm) or less. Hence XL83NL's concern. For the 33mm (1-3/8") thickness and estimating for a compound bevel,.. could be 15x2 =30 passes ?? Can it be 15hrs? XL83NL, is that what you were thinking.

Pass thickness varies by rod diameter, weld technique and groove angle(s).

Considering XL83NL question, I might have been too fast choosing 3.5mm, being too liberal for the bevel geometry for this rather thick pipe. This weld will be pretty wide at the outside surface. It should have a compound bevel, reducing the OD width, but avg pass thickness may turn out to be even less. 3.5mm works OK for estimating pipelines, usually having thinner walls, in the 5-10mm range.

So let's take a closer look.

Adjusting for weld groove angle on each pipe end, typ plain 30° bevels, or compound bevels,

This "single bevel" chart says that my number of passes estimate of 10, only works for 2x30° bevels when wall thickness is around 0.5" (12mm) or less. Hence XL83NL's concern. For the 33mm (1-3/8") thickness and estimating for a compound bevel,.. could be 15x2 =30 passes ?? Can it be 15hrs? XL83NL, is that what you were thinking.

After some internet research, with not a lot of published actual welding rate info there, what I have surmised is that downhill welding rates are for materials <= 1/2" or so and are in the 100 to 140 in/hr range. Uphill welding, typically used for thicknesses >1/2" 12mm, is going to be more like 80"/hr.

The OP's weld is going to take a long time.

The OP's weld is going to take a long time.

- Status

- Not open for further replies.

Similar threads

- Replies

- 15

- Views

- 7K

- Replies

- 3

- Views

- 7K

- Question

- Replies

- 3

- Views

- 9K

- Question

- Replies

- 2

- Views

- 9K

- Replies

- 8

- Views

- 4K