Hi, I am welding this square box of approx. 3m down to the deck of a boat with fillet welds with 6mm throat thickness. The plate is bolted to the box. The forces I have applied, Fy and Fx are expected at every corner.

I am mainly concerned about the weld, and what kind of eccentricity I might expect in this? Also, I am unsure about how to deal with the fact that this is more or less a one sided fillet weld, with the other fillet weld being 3 meters away. Could I consider a more "global" configuration, adding together the forces of two and two corners, and then consider it to be a double fillet weld?

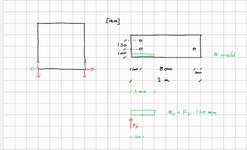

Added a picture to show what I did

I am mainly concerned about the weld, and what kind of eccentricity I might expect in this? Also, I am unsure about how to deal with the fact that this is more or less a one sided fillet weld, with the other fillet weld being 3 meters away. Could I consider a more "global" configuration, adding together the forces of two and two corners, and then consider it to be a double fillet weld?

Added a picture to show what I did