Hi,

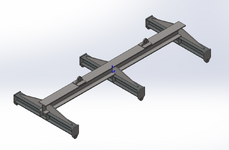

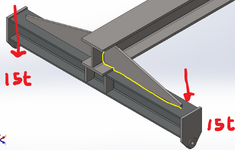

I was wondering if someone could please guide me on how to calculate the stress levels in the welds (the one shown in yellow and its opposite on the other side) for this gusset. Each of the smaller beams is to lift with 15t each end. On the larger beam, two chains from the two upper lugs will meet at 90° for a single point lift. I feel that, in one sense, the weld just adds a little to the section property of the beam but, at the other extreme, would a very small weld not just tear? Thanks.

I was wondering if someone could please guide me on how to calculate the stress levels in the welds (the one shown in yellow and its opposite on the other side) for this gusset. Each of the smaller beams is to lift with 15t each end. On the larger beam, two chains from the two upper lugs will meet at 90° for a single point lift. I feel that, in one sense, the weld just adds a little to the section property of the beam but, at the other extreme, would a very small weld not just tear? Thanks.