Hi folks,

First off, please let me know if I'm in the wrong pond with this question; I've been searching around and it seems I can't find the right search terms to find a question I'm sure has already been answered...

I do a lot of weldment drawings for my fab shop. We build heavy lifting equipment, and most of our welding is to AWS D1.1.

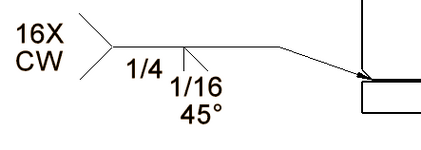

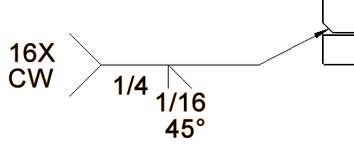

I have always placed my weld callouts so that the leader is pointing about the same angle the welder's gun will be when they are making the weld. If it's a fillet, the leaders come in about 45° on the welded side of the joint. Likewise for single bevel groove welds, the arrow is about 22.5° from the flat surface (just eyeballing).

I can't seem to find anything about it now, but I thought I stumbled across something in a google image search a couple weeks ago that implied that the leader should point to the edge that should be beveled (ultimately ending up approximately normal to the bevel), and it occurred to me that I just made up my own standard (when I started here six years ago) based on previous experience in welding school.

Just fyi, we model all of our joint prep, so all bevels that will be needed are already visible on the weldment drawing.

Is there an industry standard or a codified standard that defines the correct orientation for weld callout leaders?

Is there any reason to care if our welders are doing it right?

Thanks in advance,

Matt

First off, please let me know if I'm in the wrong pond with this question; I've been searching around and it seems I can't find the right search terms to find a question I'm sure has already been answered...

I do a lot of weldment drawings for my fab shop. We build heavy lifting equipment, and most of our welding is to AWS D1.1.

I have always placed my weld callouts so that the leader is pointing about the same angle the welder's gun will be when they are making the weld. If it's a fillet, the leaders come in about 45° on the welded side of the joint. Likewise for single bevel groove welds, the arrow is about 22.5° from the flat surface (just eyeballing).

I can't seem to find anything about it now, but I thought I stumbled across something in a google image search a couple weeks ago that implied that the leader should point to the edge that should be beveled (ultimately ending up approximately normal to the bevel), and it occurred to me that I just made up my own standard (when I started here six years ago) based on previous experience in welding school.

Just fyi, we model all of our joint prep, so all bevels that will be needed are already visible on the weldment drawing.

Is there an industry standard or a codified standard that defines the correct orientation for weld callout leaders?

Is there any reason to care if our welders are doing it right?

Thanks in advance,

Matt