Dear all,

new to the forum, so please forgive me if i am missing some information.

I am looking for some way to model a tensile test of a polymer (displacement controlled). This, in a second stage, should be used to simulate some microstructure. I have already the parametrization for particles as well as the interface. "Only" the matrix is remaining.

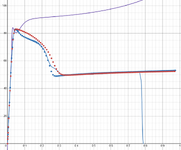

By now i have a simple elastic-plastic model, that can capture the curve of the tensile test. See attached image (purple line: elastic-plastic material curve for Abaqus, blue line: original tensile test curve, blue dots: measured curve in Abaqus). good match i would say. However, the plastic input data needs a bump (stress decrease) after the yield point to capture the behavior of the test data. That's bump is not reasonable to me, as, to my understanding, the plastic curve should be monotonic. But if keep the plastic curve monotonic i always get sth like the red curve. This is understandable, because from the materials side there is some kind of stress relaxation involved, that causes the concave shape of the curve.

As i understand from literature state of the art would be some nonlinear viscoelastic material model like parallel rheological framework. I didn't try parametrizing yet, but i don't see why it should not work (maybe running into overfitting as i have only one tensile test data). But the issue is, that i need some damage model for the second stage when simulating the microstructure. Up to now my data would work nicely with the standard ductile damage model, including triaxiality. But ductile damage does not work with the viscoelastic material model nor creep model.

So, the question is, is there some material model, that can capture this visoelastic effect or generally stress relaxation that does work with ductile damage?

Or the other way round, is there some other damage model (including triaxiality) that works with viscoelastic material models?

kind regards

Wolfgang

new to the forum, so please forgive me if i am missing some information.

I am looking for some way to model a tensile test of a polymer (displacement controlled). This, in a second stage, should be used to simulate some microstructure. I have already the parametrization for particles as well as the interface. "Only" the matrix is remaining.

By now i have a simple elastic-plastic model, that can capture the curve of the tensile test. See attached image (purple line: elastic-plastic material curve for Abaqus, blue line: original tensile test curve, blue dots: measured curve in Abaqus). good match i would say. However, the plastic input data needs a bump (stress decrease) after the yield point to capture the behavior of the test data. That's bump is not reasonable to me, as, to my understanding, the plastic curve should be monotonic. But if keep the plastic curve monotonic i always get sth like the red curve. This is understandable, because from the materials side there is some kind of stress relaxation involved, that causes the concave shape of the curve.

As i understand from literature state of the art would be some nonlinear viscoelastic material model like parallel rheological framework. I didn't try parametrizing yet, but i don't see why it should not work (maybe running into overfitting as i have only one tensile test data). But the issue is, that i need some damage model for the second stage when simulating the microstructure. Up to now my data would work nicely with the standard ductile damage model, including triaxiality. But ductile damage does not work with the viscoelastic material model nor creep model.

So, the question is, is there some material model, that can capture this visoelastic effect or generally stress relaxation that does work with ductile damage?

Or the other way round, is there some other damage model (including triaxiality) that works with viscoelastic material models?

kind regards

Wolfgang

Attachments

Last edited: