Hello everyone,

I'm currently in the process of designing a heat exchanger using Aspen, where the shellside carries liquid and the tubeside carries gas. For the liquid phase, we have RhoV² limits according to TEMA, but I’m unsure if there are similar guidelines for gas velocities.

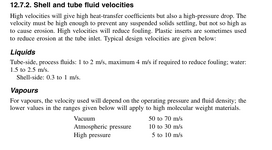

From the literature I've reviewed so far, the only typical velocity range I found for gases in tubes is between 15 m/s and 30 m/s. However, I'm not sure if this range applies to my case, because the gas is condensing—not completely, but partially.

Currently, the design uses a tubeside gas velocity of 18 m/s.

Would this be considered safe and appropriate under these conditions, or should I be concerned due to the condensation aspect?

I’d appreciate any insights or recommendations from those with experience in this area.

I'm still relatively new to this type of design work, so any insights or recommended literature would be very helpful.

Thank you!

.

I'm currently in the process of designing a heat exchanger using Aspen, where the shellside carries liquid and the tubeside carries gas. For the liquid phase, we have RhoV² limits according to TEMA, but I’m unsure if there are similar guidelines for gas velocities.

From the literature I've reviewed so far, the only typical velocity range I found for gases in tubes is between 15 m/s and 30 m/s. However, I'm not sure if this range applies to my case, because the gas is condensing—not completely, but partially.

Currently, the design uses a tubeside gas velocity of 18 m/s.

Would this be considered safe and appropriate under these conditions, or should I be concerned due to the condensation aspect?

I’d appreciate any insights or recommendations from those with experience in this area.

I'm still relatively new to this type of design work, so any insights or recommended literature would be very helpful.

Thank you!

.