dtimberlake

Mechanical

- Oct 31, 2024

- 83

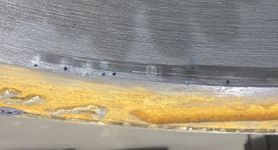

We have some 6000 lb A27 Grade 60-30. 5-7" thick. They have some defects less than .5" deep that are excavated and then weld repaired with E81T1-Ni1C flux core MIG. 100°C to 200°C preheat. PWHT 600°C ±40 °C.

Machining the large bores has problems that the machine shop says act like "hard spots."

1 - can we anneal or otherwise heat treat the part to make the welds machine like A27 Grade 60-30 steel?

2 - is there another MIG wire or SMAW filler that would machine exactly like soft, mild steel?

Thanks,

Dan T

Machining the large bores has problems that the machine shop says act like "hard spots."

1 - can we anneal or otherwise heat treat the part to make the welds machine like A27 Grade 60-30 steel?

2 - is there another MIG wire or SMAW filler that would machine exactly like soft, mild steel?

Thanks,

Dan T