CUChalk

Structural

- May 4, 2017

- 2

I am working on designing a steel-framed Vierendeel Truss using HSS verticals and wide flange chords. The reason for this is so it can effectively be hidden inside of an 8" CMU wall. There's more to the backstory of how we got to this point, but it's not relevant to my question.

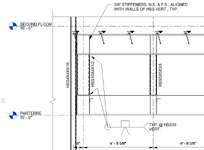

I have used RISA to size members and ensure deflections meet L/600 criteria. I have designed the moment connections for all the vertical branches to the chords using Blodgett's welded structures book and Alex T weld group spreadsheets. The final concern is how to connect this truss to the face of an HSS column that is already in place. I can't sit it on top of the column because the column extends up to a roof and this truss is at the second floor level. In my RISA model, I've used a pinned support on one end and a roller support on the other end. My question is if I have a vertical branch right at the end of the truss with significant moments at the connection points (~50 ft-kips), is it even possible to do just a shear connection or does it have to be a moment connection? Granted, even if I could theoretically do a shear tab bolted to the chord, I'm not sure you can physically do it because I need stiffener plates for the chords at each vertical-chord connection (see Revit screenshot). I have looked at pulling the end verticals back a foot from the bearing points to make room for a standard shear tab type connection (RISA screenshot).

I've never done a Vierendeel Truss so I'm just curious what a typical end connection would be in a situation like this or am I doing something unprecedented here? Any thoughts are appreciated.

Thanks in advance,

CUChalk

I have used RISA to size members and ensure deflections meet L/600 criteria. I have designed the moment connections for all the vertical branches to the chords using Blodgett's welded structures book and Alex T weld group spreadsheets. The final concern is how to connect this truss to the face of an HSS column that is already in place. I can't sit it on top of the column because the column extends up to a roof and this truss is at the second floor level. In my RISA model, I've used a pinned support on one end and a roller support on the other end. My question is if I have a vertical branch right at the end of the truss with significant moments at the connection points (~50 ft-kips), is it even possible to do just a shear connection or does it have to be a moment connection? Granted, even if I could theoretically do a shear tab bolted to the chord, I'm not sure you can physically do it because I need stiffener plates for the chords at each vertical-chord connection (see Revit screenshot). I have looked at pulling the end verticals back a foot from the bearing points to make room for a standard shear tab type connection (RISA screenshot).

I've never done a Vierendeel Truss so I'm just curious what a typical end connection would be in a situation like this or am I doing something unprecedented here? Any thoughts are appreciated.

Thanks in advance,

CUChalk