Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JAE on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

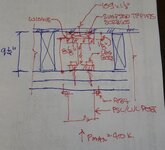

Steel Beam to Wood Post Connection

- Thread starter SE2607

- Start date

This.Not sure about @XR250 , but I have seen shallow steel flush beams in residential construction just sitting/bearing on the wall top plate just like a typical floor joist. For deeper beams or drop/soffit beams I have seen them bearing directly on a stud pack that is shorter than the typical wall studs with a tall "king" stud on each side of the beam to box it in.

- Thread starter

- #22

In my case, the joists are existing, but that's why I'm specifying PSL/LSL posts instead of green lumber.You will get a hump over the steel beam when the joists shrink...not a structural problem, but very noticeable.

ElDonFrank

Structural

- May 1, 2025

- 1

Agreed. I was just curious if you remembered the code. Would come in handy when I tell people to attach things that they haven't had to attach before...

I think it comes from ASCE 7-16:

Section 12.1.4: Connection to Supports. A positive connection for re-sisting a horizontal force acting parallel to the member shall be provided for each beam, girder, or truss either directly to its supporting elements, or to slabs designed to act as diaphragms. Where the connection is through a diaphragm, then the member’s supporting element must also be connected to the diaphragm. The connection shall have a minimum design strength of 5 percent of the dead plus live load reaction.

- Thread starter

- #24

Wow!Not sure about @XR250 , but I have seen shallow steel flush beams in residential construction just sitting/bearing on the wall top plate just like a typical floor joist. For deeper beams or drop/soffit beams I have seen them bearing directly on a stud pack that is shorter than the typical wall studs with a tall "king" stud on each side of the beam

- Thread starter

- #25

Wouldn't an end plate have to be larger (width and height) to accommodate a weld? If so, that will make it difficult to fit. In my mind, stiffeners would be the way to go....and I like steel to create torsional stability in the beam (usually an end plate).

Flotsam7018

Structural

I love this detail when crushing isn’t a problem, as opposed to terminating the top plates for a direct column connection and strapping across the beam, assuming there’s axial in the plates.

I would fasten the bottom flange to the top plates as you show, but honestly feel there’s plenty of torsional restraint between the top plates and diaphragm - contrary to another post where I argue against that very principal. I wouldn’t feel the need for the stiffeners, though it’s very standard so not a big deal to throw them in if it helps you sleep as night.

I also wouldn’t do the A34s, but am not offended by their presence.

I would fasten the bottom flange to the top plates as you show, but honestly feel there’s plenty of torsional restraint between the top plates and diaphragm - contrary to another post where I argue against that very principal. I wouldn’t feel the need for the stiffeners, though it’s very standard so not a big deal to throw them in if it helps you sleep as night.

I also wouldn’t do the A34s, but am not offended by their presence.

jerseyshore

Structural

I've put a steel beam on a wood post maybe once or twice. Never liked it even if the loads are low.

But this detail seems fine and having a positive connection is always important just for construction loads, someone or something bumping into it, etc.

But this detail seems fine and having a positive connection is always important just for construction loads, someone or something bumping into it, etc.

It can be the same dimensions as the beam (width and height). In that case the welds would be along the inside of the flanges. The plate depth can also be less with welds along the outside of the flanges.Wouldn't an end plate have to be larger (width and height) to accommodate a weld?

This.It can be the same dimensions as the beam (width and height). In that case the welds would be along the inside of the flanges. The plate depth can also be less with welds along the outside of the flanges.

I don't like stiffeners very much because the connection is so often lags or through bolts down into wood below. So there's no room for stiffeners.

Similar threads

- Replies

- 4

- Views

- 7K

- Question

- Replies

- 6

- Views

- 7K

- Replies

- 7

- Views

- 3K

- Replies

- 7

- Views

- 6K

- Replies

- 26

- Views

- 20K