theplantman

Agricultural

- Jul 2, 2025

- 5

We have recently installed a new 20hp well that runs some critical watering areas on our farm. We want to have a standby generator installed, and in reaching out to generator/electrical companies, we are getting many different opinions on what we need. As a result, I have landed here to ask for advice. Here is what we have that we want to run, and the equipment that has been installed thus far:

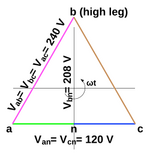

Duke Energy 230 3-phrase power (I am told this is the highest we have available)

Pump Motor: Franklin 20hp pump model #236604 Franklin Motor Link (see three attaches pages on this motor)

Danfoss VLT AQUA Drive FC-202P18KT2ERH (see photo)

(18) Greenhouse Fans. They draw 1amp each, wired 110v.

(6) Very small irrigation timers.

The most complete quote, was a custom Diesel Generator made for this application. See attached quote.

We have gotten proposals from companies for 30kw, 40kw, 65kw with either Propane or Diesel. The issue is no consistency or agreement between electricians we have reached out to, so makes us worry about selecting a company/generator and it be to small and not work, or way overkill and burn up unneeded fuel. If there are any questions or further information I need to gather, let me know!

Thanks!

Alex the farmer

Duke Energy 230 3-phrase power (I am told this is the highest we have available)

Pump Motor: Franklin 20hp pump model #236604 Franklin Motor Link (see three attaches pages on this motor)

Danfoss VLT AQUA Drive FC-202P18KT2ERH (see photo)

(18) Greenhouse Fans. They draw 1amp each, wired 110v.

(6) Very small irrigation timers.

The most complete quote, was a custom Diesel Generator made for this application. See attached quote.

We have gotten proposals from companies for 30kw, 40kw, 65kw with either Propane or Diesel. The issue is no consistency or agreement between electricians we have reached out to, so makes us worry about selecting a company/generator and it be to small and not work, or way overkill and burn up unneeded fuel. If there are any questions or further information I need to gather, let me know!

Thanks!

Alex the farmer