1/ Assumed suction ID is 6", hydraulic pressure drop @150gpm is 0.5m - see file attached.

You can reiterate results by yourself -

https://www.pressure-drop.online/

2/ Assumed water temp is 120°F water vapor pressure is 1.2m

3/ Atm pressure head is 10.5m

4/ Suction velocity head is negligble - assume 0m

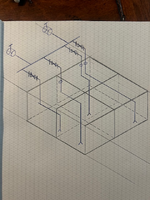

5/ ELevation difference between impeller centrline and min water level is 4.5m (as per Rymack's post above)

6/ NPSH margin as per ANSI/HI 9.6.1 is 1.0m

7/ NPSHA = 10.5 - 0.5 - 1.2 - 0 - 1.0 - 4.0 = 3.3 m

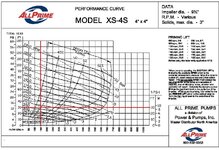

8/ NPSHR as per manufacturer's curve is 2.0m

9/ Conlculsions: 3.3>2.0 that means you have ~1.6 times safety margin. Note that the calc above is not valid if the pump capacity is actually uncontrolled.

The pump has an auto air release valve built into it

Where is it routed to? Did you see figures in a manufacturer's manual?

vertical suction from the end of the suction pipe in the tank to CL of the pump will be 4.5M

The pump is not able to pump out up to end of suction line. And the actuall elevation difference can be much lower than that expected.

Note that my calc above is not valid as I assumed that min water level will be = elevation of the end of suction line. This is not true and you and your client should understand that point the sooner the better. Suction intake design is still critical for this barge.

If we went to 5” STD pipe for suctions we would get to 2.4fps. Better?

Let's find out together.

1/ Velocity is (6"/5")^2 = 1.44 times higher

2/ Hydraulic losses are 1.44^2 = 2.1 times higher

3/ Hydraulic pressure drop @150gpm is 2.1*0.5 = 1.0m

4/ NPSHA is 3.3+0.5-1.0 = 2.8m

5/ NPSH safety margine is 2.8/2 = 1.4 times

It is up to you to compare pros and cons of these 2 options (5" vs 6") and to decide which one is preferred.

Note that the water/wastewater contains significant amount of air and this air cause cavitation of the pump classical design of. In theory in your case this air can cause loosing of priming - see the paper attached for some references.

Note that the floating debris sucked in is unable to float down and therefore it will accumulate in the pump's vacuum chamber and hinder venting. My experience with operating of the similar pump installation is that this debris is the real pain as constantly causes loosing of priming. This is why a booth screen busket or a suction strainer is desired. And undesired as has been mentioned above by forummembers.

Note that the ordinary water can be explosive, as some examples see videos of flying watertanks

The City of Lemoore has declared a State of Emergency following the deadly water tank explosion Monday afternoon.The rupture of a 1.5-million-gallon city wat...

bit.ly

An updated safety video that includes findings and recommendations from the CSB's investigation into the February 8, 2017, explosion at the Packaging Corpora...

bit.ly