Hi everyone. I'm PV engineer for carbon steel vessels by day and a farmer/rancher by night. I need to run a water line to provide water to my cows during the warm months. Currently I am using a 325 gal (US) tank in the back of a pick up truck to carry water, and I'm tired of doing it this way.

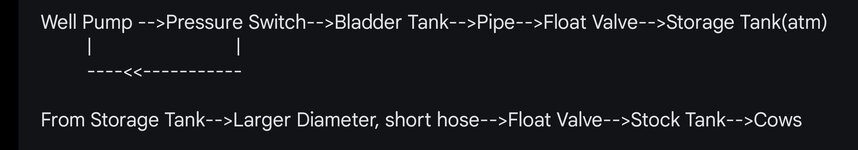

I'm planning on running the water line above ground along the perimeter fence. The total length from the current water source to the point of use is about 1600'. The good news is that I'm only looking at about 8' rise over that distance. Accounting for the hottest days and future growth of my herd, I'm wanting to design for delivering 600 gal per day. I will have the water pumped to a storage tank which will supply the water to the stock tank via gravity. This way during peak demand, the water will already be in the storage tank.

My well is on a 40/60 psi switch. I was thinking of using HDPE pipe. I was looking at flow calculations using this site: https://hdpeapp.com/#/application. I know this isn't the most comprehensive way of doing this, but...

Over 1600':

1" Pipe @ 5 GPM = 13 psi pressure drop (2 hour run time per day)

3/4" Pipe @ 5 GPM = 39 psi pressure drop (2 hour run time per day)

3/4" Pipe @ 2.5 GPM = 11 psi pressure drop (4 hour run time per day)

The 3/4" pipe and fittings will obviously be more affordable, but will it flow enough?

Is HDPE pipe a good choice for above ground water pipe? UV exposure?

I will also have to account for temperature/length changes, but should be able to accommodate that.

Am I overthinking this? Probably.

I'm planning on running the water line above ground along the perimeter fence. The total length from the current water source to the point of use is about 1600'. The good news is that I'm only looking at about 8' rise over that distance. Accounting for the hottest days and future growth of my herd, I'm wanting to design for delivering 600 gal per day. I will have the water pumped to a storage tank which will supply the water to the stock tank via gravity. This way during peak demand, the water will already be in the storage tank.

My well is on a 40/60 psi switch. I was thinking of using HDPE pipe. I was looking at flow calculations using this site: https://hdpeapp.com/#/application. I know this isn't the most comprehensive way of doing this, but...

Over 1600':

1" Pipe @ 5 GPM = 13 psi pressure drop (2 hour run time per day)

3/4" Pipe @ 5 GPM = 39 psi pressure drop (2 hour run time per day)

3/4" Pipe @ 2.5 GPM = 11 psi pressure drop (4 hour run time per day)

The 3/4" pipe and fittings will obviously be more affordable, but will it flow enough?

Is HDPE pipe a good choice for above ground water pipe? UV exposure?

I will also have to account for temperature/length changes, but should be able to accommodate that.

Am I overthinking this? Probably.