Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations cowski on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rotatign mechanism suggestion

- Thread starter SAEEDGH

- Start date

A slewing ring bearing with a drive pinion comes to mind.

dtimberlake

Mechanical

- Oct 31, 2024

- 76

rotate for fabrication?

or it will it rotate in service ?

or it will it rotate in service ?

- Thread starter

- #5

for repairing and servicerotate for fabrication?

or it will it rotate in service ?

- Thread starter

- #6

its not appropriate for this goal. i want to rotate abous green axis.A slewing ring bearing with a drive pinion comes to mind.

mfgenggear

Aerospace

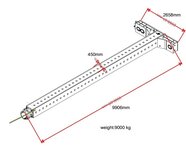

Electric rotary headView attachment 9083

hi.

i want to design a structure for rotate this part about green axis.

can you seggest me a mechanism.

dimention of part:

9906 mm

2658 mm

cross section: 450*450 mm

weight:9000kg

SAEEDGH, have you any examples of similar structures moving as you want this one to do?

You haven't bothered to tell which way this axis is oriented relative to the gravity of the Earth.

Looking forward to a complete description of all the requirements and not just a couple that make it appear to be a problem that has no solution.

You haven't bothered to tell which way this axis is oriented relative to the gravity of the Earth.

Looking forward to a complete description of all the requirements and not just a couple that make it appear to be a problem that has no solution.

You must first decide how to support it in the desired orientation. (axis horizontal, vertical, at an angle?) That means identifying the bearing locations. You haven't given us enough information to know where any interferences are, etc.

After you have established some way to support it, then you can look at how to drive it.

After you have established some way to support it, then you can look at how to drive it.

mfgenggear

Aerospace

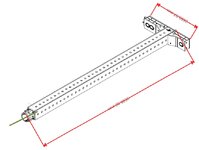

Let's try this again , let's establish axis., y, x , and z. Z would be direction of the axis. Axis w would be rotating of the entire part. Are want to rotate ot move in the z axis?View attachment 9083

hi.

i want to design a structure for rotate this part about green axis.

can you seggest me a mechanism.

dimention of part:

9906 mm

2658 mm

cross section: 450*450 mm

weight:9000kg

its not appropriate for this goal. i want to rotate abous green axis.

Only you know the reason why.

I'll assume the green axis is horizontal.

- The center of mass appears offset from the green axis, so torque will vary over each rotation. You need to calculate how much.

- You need to select a drive and brake with suitable torque in both modes, and backlash that meets your needs.

- You need to decide if the thing is stiff enough for whatever on its own, or if it needs support to limit deflection.

- You need to design and attach a physical axle on both ends. Check for shear, bending and fatigue.

- You need to select appropriate bearings or rollers.

- You need to design and build supports.

Last edited:

Similar threads

- Replies

- 6

- Views

- 2K

- Locked

- Question

- Replies

- 15

- Views

- 5K

- Locked

- Question

- Replies

- 4

- Views

- 3K

- Locked

- Question

- Replies

- 2

- Views

- 2K

- Locked

- Question

- Replies

- 3

- Views

- 2K