Eng_Struct

Structural

Hi everyone,

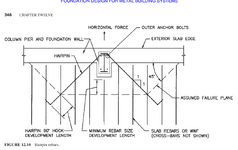

We're working on a project involving partial slab replacement in a pre-engineered metal building constructed in 1998. The existing 5" thick slab-on-grade (reinforced with wire mesh) includes hairpins from column piers for lateral thrust resistance. Although there is debate on relying on hairpins for lateral thrust through slab-on-grade (wire-mesh capacity, relying on larger tributary widths, saw-cuts causing discontinuity from column to column), the hairpins appear to be old ways of doing things and the building appears to have performed well to date with this detail.

For increased racking loads, we need to replace ~50% of the slab with a thicker, reinforced slab. The new slab will be dowelled into the existing slab using Hilti epoxy anchors, and I plan to expose existing hairpins at the columns and splice them with new rebar projecting into the new slab thus maintaining the existing detail. Unfortunately, the other half of the building (offices, etc.) must remain untouched, so I can’t replace the slab from column to column.

To maintain the tension load path in the slab:

Question:

Is there a better or more reliable way to ensure lateral load continuity between the new rebar-reinforced slab and the existing wire mesh slab, considering the constraints?

Also, are there any concerns or lessons learned with relying on epoxy dowels for this kind of tension force transfer across an old slab-on-grade?

Any thoughts or suggestions are greatly appreciated!

Thanks in advance!

We're working on a project involving partial slab replacement in a pre-engineered metal building constructed in 1998. The existing 5" thick slab-on-grade (reinforced with wire mesh) includes hairpins from column piers for lateral thrust resistance. Although there is debate on relying on hairpins for lateral thrust through slab-on-grade (wire-mesh capacity, relying on larger tributary widths, saw-cuts causing discontinuity from column to column), the hairpins appear to be old ways of doing things and the building appears to have performed well to date with this detail.

For increased racking loads, we need to replace ~50% of the slab with a thicker, reinforced slab. The new slab will be dowelled into the existing slab using Hilti epoxy anchors, and I plan to expose existing hairpins at the columns and splice them with new rebar projecting into the new slab thus maintaining the existing detail. Unfortunately, the other half of the building (offices, etc.) must remain untouched, so I can’t replace the slab from column to column.

To maintain the tension load path in the slab:

- I'm designing the dowel spacing (10M @ 8" o/c with 8" embedment) to develop the required tension due to lateral thrust across the joint. Note that the existing design appears to rely on slab tributary width equal to the column spacing for tension load development and this is what I also intend on doing

Question:

Is there a better or more reliable way to ensure lateral load continuity between the new rebar-reinforced slab and the existing wire mesh slab, considering the constraints?

Also, are there any concerns or lessons learned with relying on epoxy dowels for this kind of tension force transfer across an old slab-on-grade?

Any thoughts or suggestions are greatly appreciated!

Thanks in advance!