Hi Golfpin

Glad to hear, that you found the photos useful.

Sorry I'm on a mobile, at the moment, and can't "draw" a sketch or something, but you have to think about the rocker having three "legs/arms", but you only see two in the photo.

The small pushrod, you see connects to the rockers "invisible" leg/arm. When this pushrod moves upwards, it causes the the "leg/arm" of the rocker, which is connected to the damper top mount to move downward. It's a 180º reversal of the motion direction - think about a "classical" engine rocker, in a engine with a single low camshaft.

The best illustration, to give you an idea of the concept, I could find quickly, is the following.

just that in our case, the damper/spring unit would not connect at the center of rotation of the swingarm, but a bit more towards the right. So it would contribute a upwards motion, while the rocker is pressing the other side down - I hope that makes some sense.

It's easy to sketch, but a bit difficult to explain for a none native English speaker.

As for your other question, I'm with Greg on this one. The way I understand it, which could be wrong, you would "just" at a torsional spring to each side. It would stiffen the main suspension, but would do so in both heave, roll and single wheel bump.

It would be like trowing the anti roll bar out completely, and fitting stiffer main springs instead.

Now, without seeing the system, and how it is activated, there is the possibility, that you introduce a rising or falling rate effect.

So you perhaps, create a form of progressive (or digressive) spring rate with this, while using a linear main spring, but it doesn't do anything in "roll" specifically, unless, it does add spring rate to one side while reducing it at the other, due to some kinematic effects. Without a photo or illustration, is a bit difficult to say, with any degree of certainty.

In regards to the shown Radical system, I think Ian (murphia) is correct, and I would see it the same way.

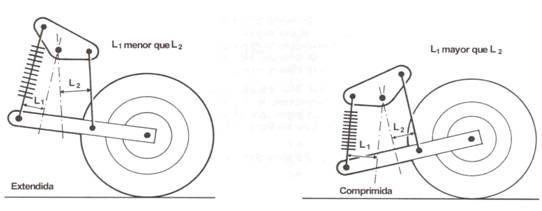

You have to systems at work. One is used to be able to modify the motion ratio of a double wishbone suspension with an diagonally mounted spring/damper unit, which employs a rocker. Similar systems you find at the back of motorcycles in different form pro-link etc.

The other is the function of the "nik-link or nic-link" which is used to link the action of one suspension side to the other. Like you do with an ARB (or sway bar)

The principle is "similar" to a "heave spring" or "3rd spring" but, while a "heave" spring would connect to the same side of the rocker, and only work, when the wheels rise or fall together, the "nik-link" is connected to the opposite side of the rocker on the other side.

Making it only/mainly work in roll.

To be able to "tune" the effect, it uses the "kink", at this point, it will flex, and thereby only transfer a part of the motion to the other side. You could use a straight link and put a spring in the middle, which would then look like a "heave spring", but connected to the opposite sides of the rocker.

The "Kink" area is quite highly stressed, and has caused issue on some cars for some sizes of links used. see photo below.

Hope this helps. When I get back to the office and have the time, I may attempt to sketch it - if it is still not 100% clear.