SelimElibol

Chemical

- Jul 10, 2025

- 4

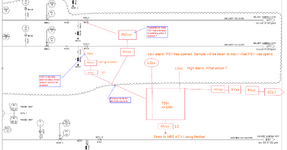

Hello I have a blocked in pipe section in a manifold for which i want to design a relief system.

The issue I have conceptually is the safe location. So downstream of each HVxx i would like to know typically what vents are used.

Now we have a full blown vessel to collect expansion of all 10 solvents but maybe thats overkill.

It consists of a vessel with low and high level alarms, and venting of that one goes to a scrubber (SCL1).

But if we want to do it like this we also need inerting with nitrogen and it starts to become problematic.

Thanks in advance for your advice and reply.

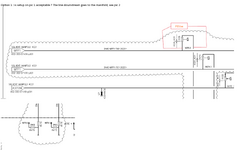

The issue I have conceptually is the safe location. So downstream of each HVxx i would like to know typically what vents are used.

Now we have a full blown vessel to collect expansion of all 10 solvents but maybe thats overkill.

It consists of a vessel with low and high level alarms, and venting of that one goes to a scrubber (SCL1).

But if we want to do it like this we also need inerting with nitrogen and it starts to become problematic.

Thanks in advance for your advice and reply.