Keystation

Structural

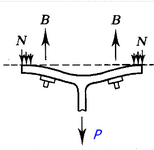

My supervisor told me to show how am I gonna account for plate bending due to prying action. My question is isn't that already part of the code?

FYI, I am using AISC15th edition and calculated tmin instead of tnp. We have a preferred design requested by the client. It would be ideal if I can get away with tmin.

Below are my understanding. Feel free to correct me. Please let me know if you have dealt with plate bending due to prying action.

tnp: Thickness that is stiff enough not allowing any bending to occur. Plate does not bend in the first place. No extra tension.

tmin: Thickness that is still stiff but allows some bending in plate. Since the equation is using Fu, yielding is acceptable. Design bolts to take that extra tension if tmin is used.

tc: Same as tmin but for angle or flange.

FYI, I am using AISC15th edition and calculated tmin instead of tnp. We have a preferred design requested by the client. It would be ideal if I can get away with tmin.

Below are my understanding. Feel free to correct me. Please let me know if you have dealt with plate bending due to prying action.

tnp: Thickness that is stiff enough not allowing any bending to occur. Plate does not bend in the first place. No extra tension.

tmin: Thickness that is still stiff but allows some bending in plate. Since the equation is using Fu, yielding is acceptable. Design bolts to take that extra tension if tmin is used.

tc: Same as tmin but for angle or flange.