Hi,

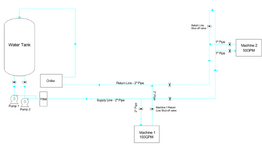

I have a process chill water loop that has been serving 1 machine very well. We recently added a 2nd machine to the loop but having issue with getting flow through it without throttle return side of the header.

Header is 2" pipe

Machine 1, 2" pipe, 150GPM

Machine 2, 1" pipe, 50GPM

Pump runs at constant speed, no VFD

Take a look at the diagram, in order to get flow through 2nd machine, I have to throttle the "Return line shut-off valve" and "Machine 1 Return Line Shut-off valve".

We will be adding a 3rd machine soon and like have better understanding of how to setup chill water loop for multiple machines with varying requirements. I think the 2nd machine doesn't have enough pressure to overcome the header pressure, hence having to throttle the return header valve. What is the best option to resolve this without manually adjusting return header. Will adding a booster pump at machine 2 work?

I have a process chill water loop that has been serving 1 machine very well. We recently added a 2nd machine to the loop but having issue with getting flow through it without throttle return side of the header.

Header is 2" pipe

Machine 1, 2" pipe, 150GPM

Machine 2, 1" pipe, 50GPM

Pump runs at constant speed, no VFD

Take a look at the diagram, in order to get flow through 2nd machine, I have to throttle the "Return line shut-off valve" and "Machine 1 Return Line Shut-off valve".

We will be adding a 3rd machine soon and like have better understanding of how to setup chill water loop for multiple machines with varying requirements. I think the 2nd machine doesn't have enough pressure to overcome the header pressure, hence having to throttle the return header valve. What is the best option to resolve this without manually adjusting return header. Will adding a booster pump at machine 2 work?