jamiethekiller

Mechanical

- May 2, 2025

- 20

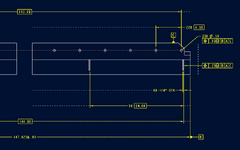

Can i use Position to locate an object on a weldment? See attached image. A is the bottom perpendicular surface.

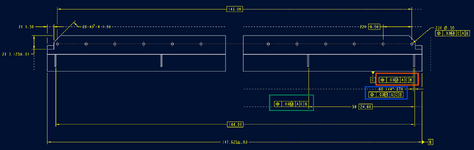

My intent is to have all of my hole patterns and gussets symmetric to weldment centerline. I have a 5x 24 basic dimension doing the spacing of the gussets. I also added a 144" basic dimension that is overall width of the end gussets. Is that 144" dimension even needed? Does the 5x 24" dimension cover intent?

Thanks

My intent is to have all of my hole patterns and gussets symmetric to weldment centerline. I have a 5x 24 basic dimension doing the spacing of the gussets. I also added a 144" basic dimension that is overall width of the end gussets. Is that 144" dimension even needed? Does the 5x 24" dimension cover intent?

Thanks