Good afternoon,

I would like to ask you a question about the NPSHr of a pump and the NPSHd.

Let's imagine a pump that has a NPSHr of 1 m. This means that the difference between the pressure at the inlet of the pump and the vapour tension needs to be at least 1 m so that it does not cavitate. Ideally, it is designed so that NPSHd is greater than NPSHr.

However, if we assume the attached drawing, in which the tank is at atmospheric pressure and the difference in height between the pump axis and the level is 40 cm and assuming that the head loss in the entire suction line is 500 mbar, that the fluid has a density of 1 g/cm3 and a very low vapour pressure at that temperature (let us say 10 mbar) and that the NPSHr of the pump is 2.8 m, the calculation of the NPSHd would give as a result (approximate):

P atm = 1 bar --> 10 m

Pvap = 10 mbar --> 0.1 m

z = 40 cm = 0.4 m

F = 500 mbar --> 5 m

NPSHd = 10 - 0.4 - 5 - 0.1 = 4.5 m

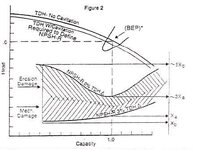

As NPSHd > NPSHr, it will not cavitate, but my question is: Now I have to see what will motivate the fluid to move towards the pump inlet. The pump will create a vacuum that will cause the fluid to move, but.... What if the pump is not able to overcome the head loss despite having a NPSHd > NPSHr? How is the NPSHd and/or NPSHr and the maximum suction capacity of the pump linked?

I would like to analyse this situation and find out what I should look for when buying a pump to know if it will be able to overcome the friction and the height and be able to move the fluid to its suction.

Thank you!

Regards

I would like to ask you a question about the NPSHr of a pump and the NPSHd.

Let's imagine a pump that has a NPSHr of 1 m. This means that the difference between the pressure at the inlet of the pump and the vapour tension needs to be at least 1 m so that it does not cavitate. Ideally, it is designed so that NPSHd is greater than NPSHr.

However, if we assume the attached drawing, in which the tank is at atmospheric pressure and the difference in height between the pump axis and the level is 40 cm and assuming that the head loss in the entire suction line is 500 mbar, that the fluid has a density of 1 g/cm3 and a very low vapour pressure at that temperature (let us say 10 mbar) and that the NPSHr of the pump is 2.8 m, the calculation of the NPSHd would give as a result (approximate):

P atm = 1 bar --> 10 m

Pvap = 10 mbar --> 0.1 m

z = 40 cm = 0.4 m

F = 500 mbar --> 5 m

NPSHd = 10 - 0.4 - 5 - 0.1 = 4.5 m

As NPSHd > NPSHr, it will not cavitate, but my question is: Now I have to see what will motivate the fluid to move towards the pump inlet. The pump will create a vacuum that will cause the fluid to move, but.... What if the pump is not able to overcome the head loss despite having a NPSHd > NPSHr? How is the NPSHd and/or NPSHr and the maximum suction capacity of the pump linked?

I would like to analyse this situation and find out what I should look for when buying a pump to know if it will be able to overcome the friction and the height and be able to move the fluid to its suction.

Thank you!

Regards

![[neutral] [neutral] [neutral]](/data/assets/smilies/neutral.gif) .

.