stn-cadams

Civil/Environmental

- May 4, 2025

- 2

Hi all,

My company (municipal engineering firm) have been engaged to design a factory coated bolted-steel water tank for fire protection service. The tank feeds a NFPA 20 compliant fire pump and NFPA 13 compliant sprinkler system. Sizing has been performed by a fire protection engineer, we are required to design the tank complete with drains, fill and discharge lines in accordance with NFPA 22.

We frequently design these in accordance with AWWA D103 for municipal water supply but are new to aligning to the NFPA 22 code. I am looking for clarity on some nuances in NFPA 22 outlined below.

Below Grade Piping:

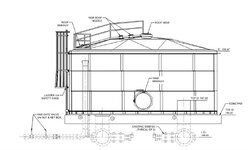

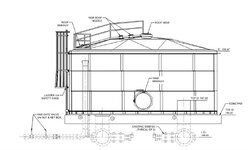

NFPA 22 12.6.4 and 12.6.4.1: This project is located in Canada, our typical design for factory coated bolted-steel reservoirs (constructed at grade) is to have pipes come below the tank foundation (typical design shown below). Does this design conflict with 12.6.4 or since the bottom of the foundation is below grade are pipes below the foundation permitted? Would the pipes need to be encased in the concrete foundation to adhere to this?

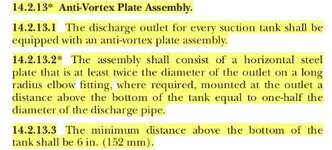

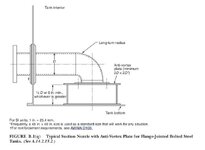

Anti-Votex Plate:

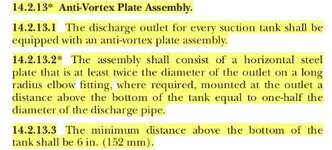

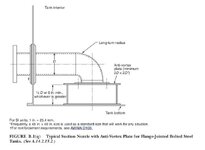

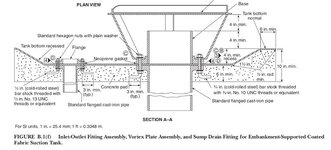

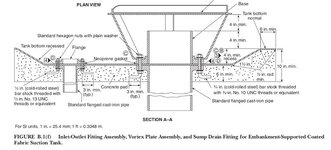

Per NFPA 22 14.2.13 every suction tank is required to include an anti-vortex plate. Typical installation has the suction piping leave the tank above grade with a minimum clearance from the floor. Ideally, I would like to provide a tank drain and outlet on the bottom of the floor (with below grade piping). Based on my understanding of the code, there is no specific outline of how to do this other than the schematic shown for concrete lined embankment supported suction tanks. It seems fair to me to use this installation for my proposed purpose. Any thoughts on this would be appreciated. Is anyone aware of a standard product (floor mounted vortex plate assembly) for this purpose?

Thank you in advance for your help,

My company (municipal engineering firm) have been engaged to design a factory coated bolted-steel water tank for fire protection service. The tank feeds a NFPA 20 compliant fire pump and NFPA 13 compliant sprinkler system. Sizing has been performed by a fire protection engineer, we are required to design the tank complete with drains, fill and discharge lines in accordance with NFPA 22.

We frequently design these in accordance with AWWA D103 for municipal water supply but are new to aligning to the NFPA 22 code. I am looking for clarity on some nuances in NFPA 22 outlined below.

Below Grade Piping:

NFPA 22 12.6.4 and 12.6.4.1: This project is located in Canada, our typical design for factory coated bolted-steel reservoirs (constructed at grade) is to have pipes come below the tank foundation (typical design shown below). Does this design conflict with 12.6.4 or since the bottom of the foundation is below grade are pipes below the foundation permitted? Would the pipes need to be encased in the concrete foundation to adhere to this?

Anti-Votex Plate:

Per NFPA 22 14.2.13 every suction tank is required to include an anti-vortex plate. Typical installation has the suction piping leave the tank above grade with a minimum clearance from the floor. Ideally, I would like to provide a tank drain and outlet on the bottom of the floor (with below grade piping). Based on my understanding of the code, there is no specific outline of how to do this other than the schematic shown for concrete lined embankment supported suction tanks. It seems fair to me to use this installation for my proposed purpose. Any thoughts on this would be appreciated. Is anyone aware of a standard product (floor mounted vortex plate assembly) for this purpose?

Thank you in advance for your help,