-

1

- #1

structural_engineer

Structural

TLDR version: Is everyone using pre-qualified fasteners to connect their steel stud walls to concrete slabs in light of Clause 4.1.8.18.(7)(d)) of the NBC 2020?

First off, this is my first Eng-Tips post, so apologies if I get any of the procedures wrong. I did search for answers to this post on Eng-Tips, but was unable to find anything on this specifically.

We're reviewing our anchorage details for steel stud wall tracks to concrete slabs in light of the new requirements in the NBC 2020. A bit late to this discussion, but the seismic aspects of the BCBC 2024 (based on the NBC 2020) only recently came into effect for newly permitted buildings in BC and most of the projects we provide specialty engineering for have fallen under the BCBC 2018, thus far. Specifically, NBC 2020 requires post-installed mechanical, drop-in, and adhesive anchors in concrete to be pre-qualified for seismic applications by cyclic load testing per CSA A23.3 or ACI 355.2/355.4:

This seems to mark a big shift from NBC 2015, which didn’t include this pre-qualification requirement. In fact, NBC 2015 did not have this clause and simply stated:

We’ve typically used Hilti HMH hammer-set nail-in anchors [or PAFs (powder-actuated fasteners) (depending on the location and application)] to connect steel stud bottom tracks to concrete, and under NBC 2015, this was acceptable. These anchors aren’t drop-in style and were not acting in tension, so they didn’t trigger any of the old limitations. Ironically, the updated clauses actually allow pre-qualified drop-in anchors (like the Hilti HDI-P TZ), which were previously prohibited under the NBC 2015.

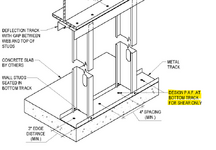

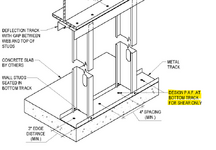

A document detailing how PAFs are used in steel stud wall framing can be found here. The snip below is taken from that the lined document from the CFSEI titled "POWER-ACTUATED FASTENERS IN COLD-FORMED STEEL CONSTRUCTION". This document also lists how, in the US, PAFs can be used in seismic zones provided they meet certain load limitations.

That said, under NBC 2020 (and now BCBC 2024), it seems HMH anchors and PAFs are no longer acceptable for any walls experiencing even minimal seismic shear (like <10 lb per PAF - which we ran into recently on a post-disaster project in Saskatchewan).

Hilti confirmed the HMH isn't pre-qualified. They’ve recommended three alternatives that are:

Curious what others are using to meet this new clause. Are others specifying drilled-in pre-qualified anchors for all top and bottom tracks now? Seems like a pretty radical change to construction processes and I don't see any discussion of this implication online.

First off, this is my first Eng-Tips post, so apologies if I get any of the procedures wrong. I did search for answers to this post on Eng-Tips, but was unable to find anything on this specifically.

We're reviewing our anchorage details for steel stud wall tracks to concrete slabs in light of the new requirements in the NBC 2020. A bit late to this discussion, but the seismic aspects of the BCBC 2024 (based on the NBC 2020) only recently came into effect for newly permitted buildings in BC and most of the projects we provide specialty engineering for have fallen under the BCBC 2018, thus far. Specifically, NBC 2020 requires post-installed mechanical, drop-in, and adhesive anchors in concrete to be pre-qualified for seismic applications by cyclic load testing per CSA A23.3 or ACI 355.2/355.4:

“post-installed mechanical, drop-in and adhesive anchors in concrete shall be pre-qualified for seismic applications by cyclic load testing in accordance with: i) CSA A23.3… ii) ACI 355.2 or ACI 355.4…” (NBC 2020 Clause 4.1.8.18.(7)(d))

This seems to mark a big shift from NBC 2015, which didn’t include this pre-qualification requirement. In fact, NBC 2015 did not have this clause and simply stated:

It seems that the NBC 2020 has added two extra clauses before Clause 4.1.8.18 (7)(d)) from the NBC 2015. The above clause from the NBC 2015 is included as clause (f) in the NBC 2020.“power-actuated fasteners and drop-in anchors shall not be used for tension loads.” (NBC 2015 Clause 4.1.8.18 (7)(d))

We’ve typically used Hilti HMH hammer-set nail-in anchors [or PAFs (powder-actuated fasteners) (depending on the location and application)] to connect steel stud bottom tracks to concrete, and under NBC 2015, this was acceptable. These anchors aren’t drop-in style and were not acting in tension, so they didn’t trigger any of the old limitations. Ironically, the updated clauses actually allow pre-qualified drop-in anchors (like the Hilti HDI-P TZ), which were previously prohibited under the NBC 2015.

A document detailing how PAFs are used in steel stud wall framing can be found here. The snip below is taken from that the lined document from the CFSEI titled "POWER-ACTUATED FASTENERS IN COLD-FORMED STEEL CONSTRUCTION". This document also lists how, in the US, PAFs can be used in seismic zones provided they meet certain load limitations.

That said, under NBC 2020 (and now BCBC 2024), it seems HMH anchors and PAFs are no longer acceptable for any walls experiencing even minimal seismic shear (like <10 lb per PAF - which we ran into recently on a post-disaster project in Saskatchewan).

Hilti confirmed the HMH isn't pre-qualified. They’ve recommended three alternatives that are:

- Hilti KH-EZ

- Hilti KB-TZ

- Hilti HDI-P TZ

Curious what others are using to meet this new clause. Are others specifying drilled-in pre-qualified anchors for all top and bottom tracks now? Seems like a pretty radical change to construction processes and I don't see any discussion of this implication online.