Hello there!

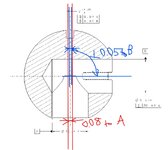

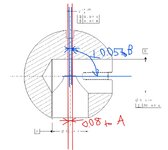

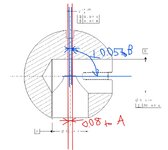

I've got a ball here for discussion. The ball is constrained between seating elements and is rotated around Datum A by the slot on top.

My coworker made the decision to give that slot two different position tolerances.

His idea: 0.08 concentricity to A because the offset isn't that important here.

0.05 to B because the right angle is more important in the ball function.

I have objected his proposal because in my understanding, this callout on 2+0,05 applies as the following:

Top row means concentricity to A.

Bot row means perpendicularity to B.

0.05 < 0.08 hence the top row is meaningless.

His explanation:

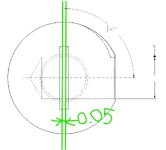

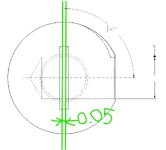

Top row applies in the upper view as discussed. Bot row applies in top view like this:

Important note: This view is NOT PRESENT on the drawing, I have made it to explain this visually.

What is the correct interpretation of the multiple segment callout?

Who's in the wrong here?

I've got a ball here for discussion. The ball is constrained between seating elements and is rotated around Datum A by the slot on top.

My coworker made the decision to give that slot two different position tolerances.

His idea: 0.08 concentricity to A because the offset isn't that important here.

0.05 to B because the right angle is more important in the ball function.

I have objected his proposal because in my understanding, this callout on 2+0,05 applies as the following:

Top row means concentricity to A.

Bot row means perpendicularity to B.

0.05 < 0.08 hence the top row is meaningless.

His explanation:

Top row applies in the upper view as discussed. Bot row applies in top view like this:

Important note: This view is NOT PRESENT on the drawing, I have made it to explain this visually.

What is the correct interpretation of the multiple segment callout?

Who's in the wrong here?