adam0bmx0

Marine/Ocean

- Apr 10, 2009

- 5

Hi chaps,

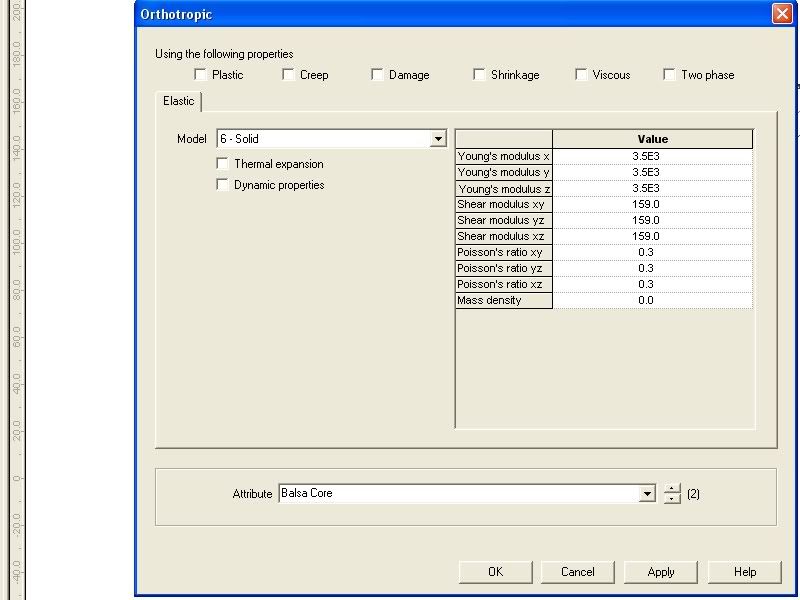

Basically i need to add a new material in Lusas Comosite, i want to add a typical 'End Grain Balsa'. Ive already checked in the avialible materials supplied in the software and there is no Balsa.

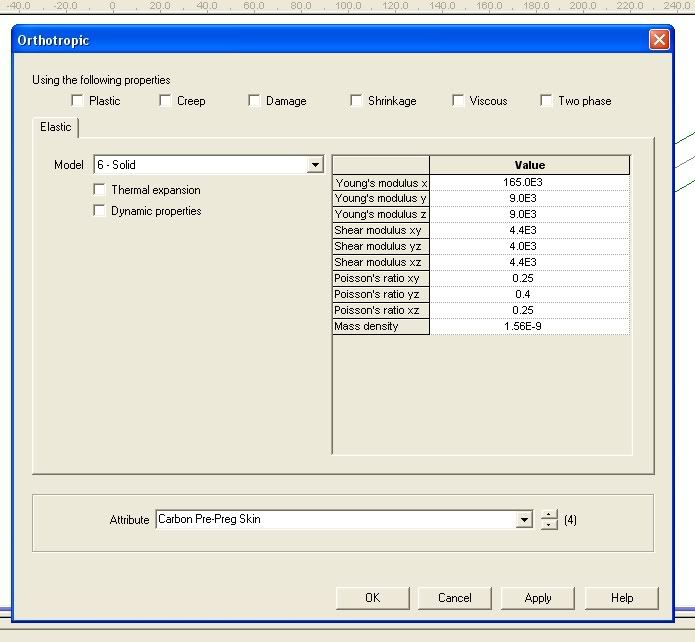

I've attached 2 pictures, one shows the inputs in the Lusas software i need to input, and the other is the information im using for Balsa.

Im stuck on what to put in the Lusas software.

Any help is much appreciated.

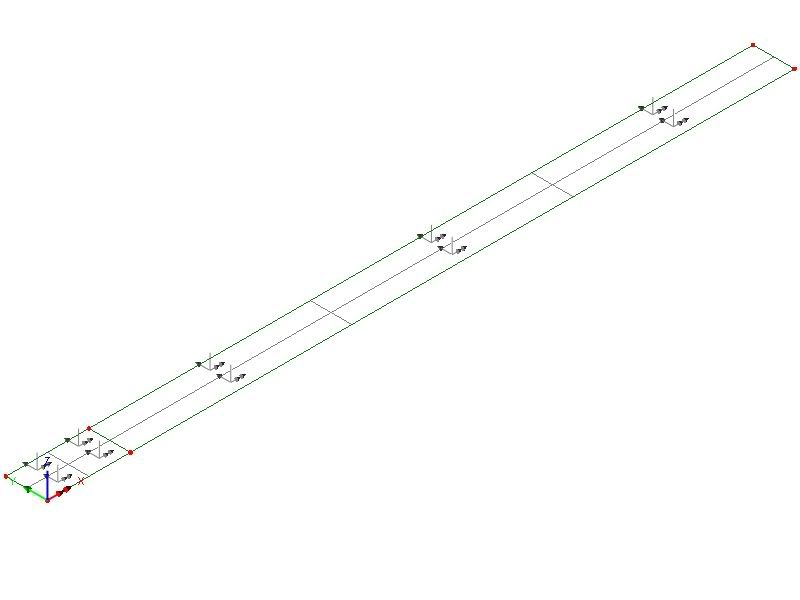

For reference im trying to model a 3-point bending test on a sandiwch composite, carbon skins with a balsa core.

Cheers,

Adam

Basically i need to add a new material in Lusas Comosite, i want to add a typical 'End Grain Balsa'. Ive already checked in the avialible materials supplied in the software and there is no Balsa.

I've attached 2 pictures, one shows the inputs in the Lusas software i need to input, and the other is the information im using for Balsa.

Im stuck on what to put in the Lusas software.

Any help is much appreciated.

For reference im trying to model a 3-point bending test on a sandiwch composite, carbon skins with a balsa core.

Cheers,

Adam