Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JAE on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for stud wall bearing capacity tables 1

- Thread starter robinasu

- Start date

- Status

- Not open for further replies.

msquared48

Structural

I do not think you will find anything for a 20' height of stud. Probably have to figure it out and several things will enter into the mix here to determine the capacity.

That being said though, are you just looking for vertical capacity, neglecting any wind load?

Mike McCann, PE, SE (WA)

That being said though, are you just looking for vertical capacity, neglecting any wind load?

Mike McCann, PE, SE (WA)

- Thread starter

- #3

MacGruber22

Structural

Why are you not hiring a structural engineer? What are you doing with this stud wall? These forums are not exactly for this sort of help usually.

If it is for an exterior wall of a house, the stud wall will have 1/2" plywood on the outside and 5/8" drywall on the inside. After all there are organizations that have done tests on thermal conductivity and fire resistance rating of such assembly. I would say that there is publication but the problem is to find out which organization is printing it out. I would say research plywood and dressed lumber organizations and check into Canadian organizations.

Try researching this link which I copied from thread Wood Warping (#337-374204).

Assume you are using wood

IRC Code Requirements for Wall Systems Limits on size and spacing: Table R602.3(5) limits stud height to 10’, size to 2 x 6 and spacing to 16” for homes with 2 floors, roof and ceiling. For wall systems higher then 10 feet, engineering is required.

Consider using Woodworks Sizer Software or Forte® Software

use eccentric axial loading of 1/6th the stud depth

hardware for stud to plate to handle the out of plane connection, refer to manufacturer’s installation guide.

Analyze studs for combined axial and bending loading.

Methodology

1.Determine lumber design values, Fb, F’b, Fc, F’c, E, E’

2.Determine stress from load cases.

3.Check critical buckling.

4.Use interaction equation to proportion member.

5.Check span for bending using components and cladding pressure.

Axial Load, La

*Load case: W + D + Lr will govern,

La=W + D + Lr

Bending Load, Fb

*Load case: w (MWFRS)

Fb=(w*L**2)/(8*s)

Critical column buckling stress, FcE1

FcE1=(KcE*E’)/((Le/d)**2)

Interaction equation to check member capacities for combined loading.

((fc/Fc')**2)+(fb/(Fb'(1-(fc/FcE)))lessthanequal 1.0

I specify and use #2 or #1 for the increase in strength and diminsional stability. Homedepot ad local lumer yards carries the higher grade lumber in both white woods and SYP.

Using Fb SPF stud 675 psi

Adjusted value

Adjustment Factors

•Cd=1.6 (Fb, Fc)

load duration

•Cr = 1.4 (2x6) & 1.5 (2x4), (Fb,)

repetitive member

IBC, Table 2306.2.1

•Cf = 1.5 (Fb)& 1.15 (Fc)

size factorUse with Hem Fir

Factors included in values for SYP

•CL = 1.0

lateral stability, assume wall sheathed

•F’b = 675 psi (1.6)(1.5)(1.5) = 2,430 psi allowable

Some building code allows a stress increase for stud walls with plywood sheathing one the exterior surface and gyp board on the inside.

Check deflection limit L/240 corresponds for current code and Live Load = Wind and brittle wall finish. See IBC Table 1604.3

IRC Code Requirements for Wall Systems Limits on size and spacing: Table R602.3(5) limits stud height to 10’, size to 2 x 6 and spacing to 16” for homes with 2 floors, roof and ceiling. For wall systems higher then 10 feet, engineering is required.

Consider using Woodworks Sizer Software or Forte® Software

use eccentric axial loading of 1/6th the stud depth

hardware for stud to plate to handle the out of plane connection, refer to manufacturer’s installation guide.

Analyze studs for combined axial and bending loading.

Methodology

1.Determine lumber design values, Fb, F’b, Fc, F’c, E, E’

2.Determine stress from load cases.

3.Check critical buckling.

4.Use interaction equation to proportion member.

5.Check span for bending using components and cladding pressure.

Axial Load, La

*Load case: W + D + Lr will govern,

La=W + D + Lr

Bending Load, Fb

*Load case: w (MWFRS)

Fb=(w*L**2)/(8*s)

Critical column buckling stress, FcE1

FcE1=(KcE*E’)/((Le/d)**2)

Interaction equation to check member capacities for combined loading.

((fc/Fc')**2)+(fb/(Fb'(1-(fc/FcE)))lessthanequal 1.0

I specify and use #2 or #1 for the increase in strength and diminsional stability. Homedepot ad local lumer yards carries the higher grade lumber in both white woods and SYP.

Using Fb SPF stud 675 psi

Adjusted value

Adjustment Factors

•Cd=1.6 (Fb, Fc)

load duration

•Cr = 1.4 (2x6) & 1.5 (2x4), (Fb,)

repetitive member

IBC, Table 2306.2.1

•Cf = 1.5 (Fb)& 1.15 (Fc)

size factorUse with Hem Fir

Factors included in values for SYP

•CL = 1.0

lateral stability, assume wall sheathed

•F’b = 675 psi (1.6)(1.5)(1.5) = 2,430 psi allowable

Some building code allows a stress increase for stud walls with plywood sheathing one the exterior surface and gyp board on the inside.

Check deflection limit L/240 corresponds for current code and Live Load = Wind and brittle wall finish. See IBC Table 1604.3

racookpe1978

Nuclear

See above for details, but you're claiming a 3x 6 stud wall?

Even 2x "2x4" would be 3" x 3.5" (if glued or scrwed together) but "naile together" (or just back-to-back assembly) would not give you a lot of combiend strength. Quantity two 2x6 wood boards fastened together would yield 3 x 5.5. Again, not the dimension you started with.

Even 2x "2x4" would be 3" x 3.5" (if glued or scrwed together) but "naile together" (or just back-to-back assembly) would not give you a lot of combiend strength. Quantity two 2x6 wood boards fastened together would yield 3 x 5.5. Again, not the dimension you started with.

woodman88

Structural

- Oct 23, 2009

- 1,020

Typically, using 2-2x studs in wood walls are used to increase the spacing of the studs. Say you need 2x at 4"o.c. or 6"o.c. you can use a 2-2x at 8"o.c. or 12"o.c.. For this reason nailing them together is acceptable. No reason to screw or glue them together.

Garth Dreger PE - AZ Phoenix area

As EOR's we should take the responsibility to design our structures to support the components we allow in our design per that industry standards.

Garth Dreger PE - AZ Phoenix area

As EOR's we should take the responsibility to design our structures to support the components we allow in our design per that industry standards.

-

1

- #12

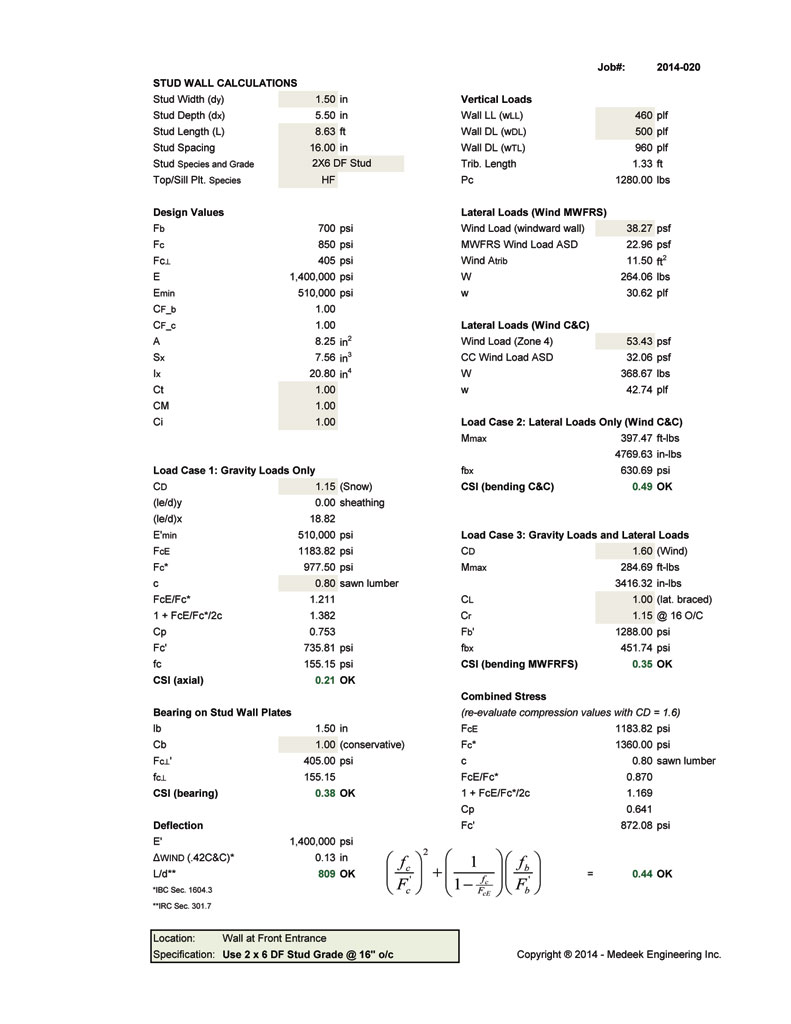

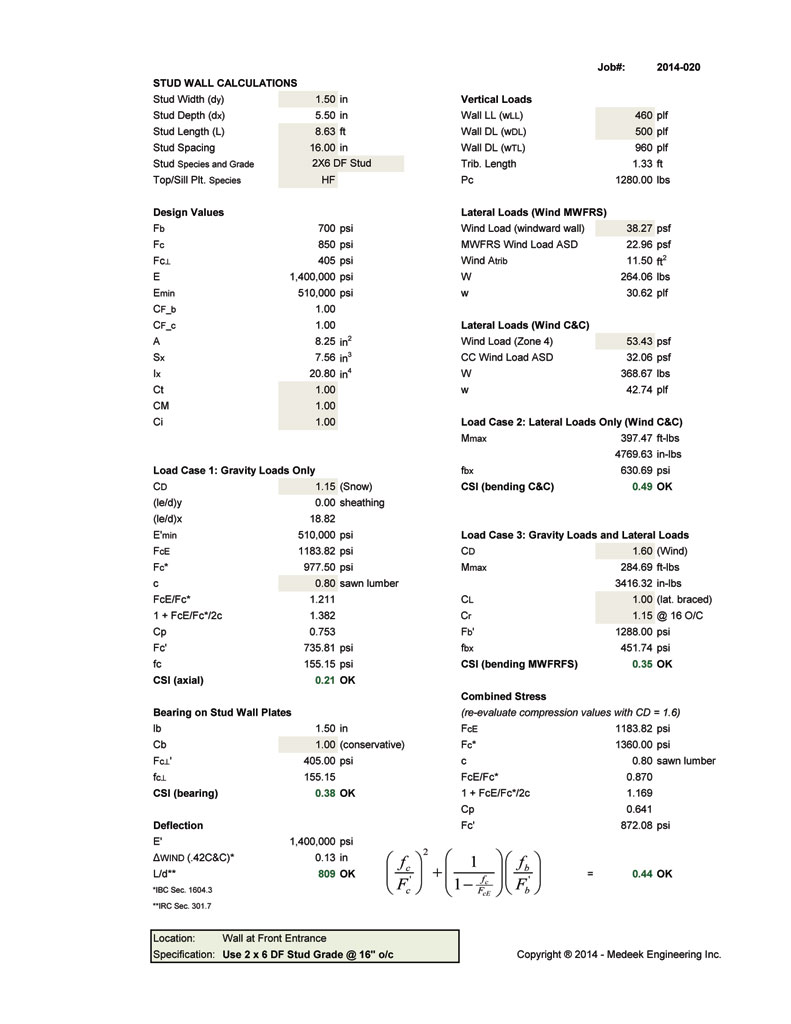

Here is a typical studwall calculation using an Excel spreadsheet:

I am checking:

1. Axial loading only

2. Lateral loading only (C&C Wind Loads)

3. Combined Axial and Lateral loads (using MWFRS wind pressures)

4. Bearing on the sill/top plate

5. Deflection based on C&C wind loading only.

The combined calculation (3) is conservative since I am not taking any reductions (75%) for live loads that combine Lr, L, S and W.

A confused student is a good student.

I am checking:

1. Axial loading only

2. Lateral loading only (C&C Wind Loads)

3. Combined Axial and Lateral loads (using MWFRS wind pressures)

4. Bearing on the sill/top plate

5. Deflection based on C&C wind loading only.

The combined calculation (3) is conservative since I am not taking any reductions (75%) for live loads that combine Lr, L, S and W.

A confused student is a good student.

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 7K

- Replies

- 8

- Views

- 3K

- Locked

- Question

- Replies

- 3

- Views

- 1K