Hi all,

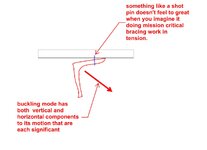

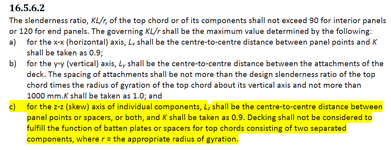

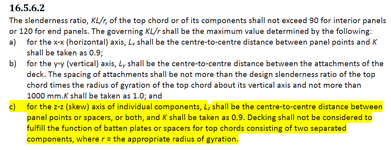

I am wondering what the accepted way to interpret this clause regarding joist top chords is. I have spoken with reps from different joist manufacturers where they all said that they take the value of Lz as zero (or 1mm to make it not govern) for B2B angle top chords, typically with a gap of 1" between pieces. It was explained to me that the way the Lz fails is by flattening the angle out along it's skew axis and the deck restrains it. That being said, S16 appears to directly prohibit doing this.

Subsequently, for shapes where the principle axes are the same as the axes by which the joist is loaded, such as a hat channel or an omega joist, does this imply that there is no skew angle and the Lz check can be omitted? (Angles are listed in the table with axes parallel to the legs, as well as the principle axes. The way by which angles bend is outlined in this article by Graitec)

When I run a calculation for compressive resistance of a hat channel joist, there is a large difference in strength when I put in Lz as my panel point spacing, vs taking it as non-governing since there is no skew axis. I just want to make sure I'm not being unconservative by ignoring the Lz.

I am wondering what the accepted way to interpret this clause regarding joist top chords is. I have spoken with reps from different joist manufacturers where they all said that they take the value of Lz as zero (or 1mm to make it not govern) for B2B angle top chords, typically with a gap of 1" between pieces. It was explained to me that the way the Lz fails is by flattening the angle out along it's skew axis and the deck restrains it. That being said, S16 appears to directly prohibit doing this.

Subsequently, for shapes where the principle axes are the same as the axes by which the joist is loaded, such as a hat channel or an omega joist, does this imply that there is no skew angle and the Lz check can be omitted? (Angles are listed in the table with axes parallel to the legs, as well as the principle axes. The way by which angles bend is outlined in this article by Graitec)

When I run a calculation for compressive resistance of a hat channel joist, there is a large difference in strength when I put in Lz as my panel point spacing, vs taking it as non-governing since there is no skew axis. I just want to make sure I'm not being unconservative by ignoring the Lz.

Last edited: