Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations TugboatEng on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How can I calculate the temperature at the end of a Pipe Trunnion 2

- Thread starter ellas1

- Start date

- Status

- Not open for further replies.

-

1

- #2

LittleInch

Petroleum

You can't to any degree of certainty. You could try some fancy CFD.

A temperature probe is you best bet when it's running.

The variables include wind speed, insulation thickness, indoors / out doors, rain, snow, sun, length of trunnion etc etc

Just assume it's the temperature of the main pipe and you'll be ok.

Relying on anything else to reduce that temp is foolish (IMHO)

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

A temperature probe is you best bet when it's running.

The variables include wind speed, insulation thickness, indoors / out doors, rain, snow, sun, length of trunnion etc etc

Just assume it's the temperature of the main pipe and you'll be ok.

Relying on anything else to reduce that temp is foolish (IMHO)

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

SuperSalad

Chemical

I was thinking something similar to LittleInch's comment above. You could develop a pretty sophisticated model that might approximate it relatively well. But to what purpose? I would personally rather take the conservative approach of assuming the steam temperature is the maximum the trunnion would experience and design based off of that. Unless the trunnion is made from some exotic material or extremely large/long (ie. prohibitively expensive), I would think that would be the better option.

Andrew H.

Andrew H.

-

1

- #4

- Thread starter

- #5

LittleInch

Petroleum

How long is "very long"?

There was something similar here about temperature of a dead leg I think. I'll see if I can find it, but from what I recall this also was a hybrid set of heat energy vs convection etc.

It was this one but less helpful than I recall

But the basis is the same - energy in and along the trunnion ( soild or a hollow pipe?) miuns heat losses from convection ( well known fomulae) and the repeat in small sections. You should get a parabolic temp curve vs distance from the pipe.

But a drawing, sketch or photo would help a lot.

So deciding on what your parameters are for how this pipe trunnion cools is a key part of the thinking, e.g. natural convection or forced / wind and then work from there.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

There was something similar here about temperature of a dead leg I think. I'll see if I can find it, but from what I recall this also was a hybrid set of heat energy vs convection etc.

It was this one but less helpful than I recall

But the basis is the same - energy in and along the trunnion ( soild or a hollow pipe?) miuns heat losses from convection ( well known fomulae) and the repeat in small sections. You should get a parabolic temp curve vs distance from the pipe.

But a drawing, sketch or photo would help a lot.

So deciding on what your parameters are for how this pipe trunnion cools is a key part of the thinking, e.g. natural convection or forced / wind and then work from there.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

Whaaat ??........ A very long trunnion welded to a steam pipe ??!~~

This doesn't sound very good .....

Integral Welded attachments (lugs, trunions, clips etc) should rarely be used to support piping systems and, IMHO, NEVER on Steam piping systems

Yes, I understand that you are new to this job, a recent graduate and the Client wants this done right away.....

Can you provide photos or sketches to help us out here ??

How about details of the steam piping system ? Pressures, temperatures and materials ?

What is the material of the trunnion ?

Do you have a cell phone that you can take pictures with ?

MJCronin

Sr. Process Engineer

This doesn't sound very good .....

Integral Welded attachments (lugs, trunions, clips etc) should rarely be used to support piping systems and, IMHO, NEVER on Steam piping systems

Yes, I understand that you are new to this job, a recent graduate and the Client wants this done right away.....

Can you provide photos or sketches to help us out here ??

How about details of the steam piping system ? Pressures, temperatures and materials ?

What is the material of the trunnion ?

Do you have a cell phone that you can take pictures with ?

MJCronin

Sr. Process Engineer

LittleInch

Petroleum

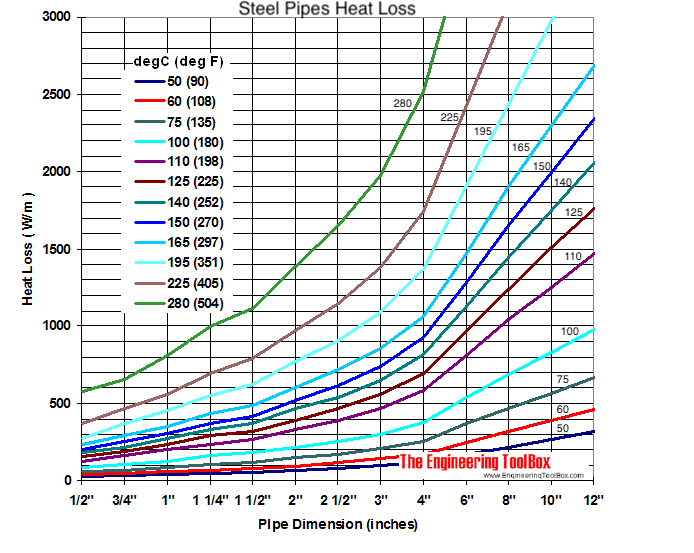

To use that graph you need to then split the trunnion into short lend as the temperature will then vary along its length as it's only heated from one end.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

Compositepro

Chemical

What is the problem you suspect that you want to solve? Generally, if you want to keep something from getting hot, when it is connected to something hot, you apply some cooling between it and the heat source. Steel is not a great heat conductor,so cooling fins often solve any problem.

LittleInch

Petroleum

I usually find steel is quite a good conductor of heat....

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

Trunnions have been around for a long time and are frequently the cause of steam piping system failure and accidents. Failure by long term fatigue is a concern

Trunnions on piping elbows are a "not recommended" design and IMHO, only tolerable on low temperature (less than 300F) systems.

Elbow Trunnions are a challenge for the piping fabricator and the welders !!!

Trunnions complicate the stress analysis of the piping system needlessly.

EPRI, recognizing the implicit long term fatigue threat of elbow trunnions, issued this report/ guideline for those troublesome supports.

There is always a simpler and safer way to support systems rather than using elbow trunnions

MJCronin

Sr. Process Engineer

Trunnions on piping elbows are a "not recommended" design and IMHO, only tolerable on low temperature (less than 300F) systems.

Elbow Trunnions are a challenge for the piping fabricator and the welders !!!

Trunnions complicate the stress analysis of the piping system needlessly.

EPRI, recognizing the implicit long term fatigue threat of elbow trunnions, issued this report/ guideline for those troublesome supports.

There is always a simpler and safer way to support systems rather than using elbow trunnions

MJCronin

Sr. Process Engineer

Common problem in our designs. We usually model the trunnion at the full or near steam temperature. Expansion of the trunnion may lift off adjacent supports so the stress model and solution should be conservative. A very long hot trunnion may clause more problems than it is worth.

From experience long uninsulated trunnions outside on 150 -200C steam lines do not get near the temperature of the steam line. But they will be hotter than support steel.

From experience long uninsulated trunnions outside on 150 -200C steam lines do not get near the temperature of the steam line. But they will be hotter than support steel.

LittleInch

Petroleum

I really don't understand the issue here though. Whatever the expansion of the trunnion it will be dwarfed by the expansion of the pipe. You need to allow things to move in a controlled manner.

A drawing, photo or diagram would help a LOT.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

A drawing, photo or diagram would help a LOT.

Remember - More details = better answers

Also: If you get a response it's polite to respond to it.

Lisega had several papers on the pipe supports and temperature distribution. I cannot reach them at the moment but, from the memory, every mm distance from the heat source on the pipe cause around 2 deg C reduction of temperature on the pipe supports of steam piping.

You probably contact Lisega for the related paper.

Hope it helps.

You probably contact Lisega for the related paper.

Hope it helps.

I am willing to bet that this question was posted by someone who is modelling a trunnion into a CAESAR-II piping analysis.

He was confronted by a box asking for the temperature of the trunnion elements and wants his model to be more accurate....

MJCronin

Sr. Process Engineer

He was confronted by a box asking for the temperature of the trunnion elements and wants his model to be more accurate....

MJCronin

Sr. Process Engineer

- Status

- Not open for further replies.

Similar threads

- Question

- Replies

- 8

- Views

- 970

- Question

- Replies

- 7

- Views

- 3K

- Question

- Replies

- 5

- Views

- 688

- Locked

- Question

- Replies

- 2

- Views

- 3K