BridgeEngineer21

Structural

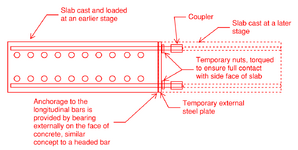

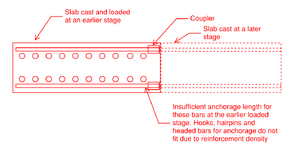

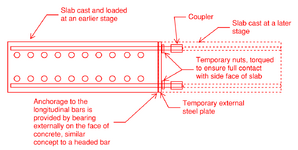

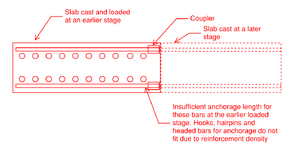

I have a situation that I can't seem to find any examples of in practice. During staged construction, a slab is loaded right to the edge, utilizing the primary longitudinal reinforcement. These bars will eventually be coupled and continue into the next stage of the slab (figure 1). But temporarily, they need to be anchored somehow. We've proposed various solutions like hairpin bars and additional headed bars, but the reinforcement density is quite dense, so for ease of constructability the contractor has asked about this alternate solution to anchor the bars externally, to a steel plate at the face of the slab (figure 2).

In principle it is very similar to headed bar anchors, but I guess the capacity of those is based on manufacturer testing that would include things like the effects of bond between head and concrete and confinement of adjacent concrete, which aren't present here. In theory, it seems possible and easy to just verify the bearing capacity of the concrete behind the plate, as well as the required torque on the nuts to ensure the plate is tight against the face of concrete. But I'm a bit unsure about using a solution which there is seemingly no precedent for, at least not in any code or reference about rebar anchorage I can find. It's more comparable to post-tensioning - but we're not using post-tensioning bars here.

Has anyone seen something like this before? And if not, can anyone think of any concerns or reasons this wouldn't work that I'm maybe not identifying?

Figure 1:

Figure 2:

In principle it is very similar to headed bar anchors, but I guess the capacity of those is based on manufacturer testing that would include things like the effects of bond between head and concrete and confinement of adjacent concrete, which aren't present here. In theory, it seems possible and easy to just verify the bearing capacity of the concrete behind the plate, as well as the required torque on the nuts to ensure the plate is tight against the face of concrete. But I'm a bit unsure about using a solution which there is seemingly no precedent for, at least not in any code or reference about rebar anchorage I can find. It's more comparable to post-tensioning - but we're not using post-tensioning bars here.

Has anyone seen something like this before? And if not, can anyone think of any concerns or reasons this wouldn't work that I'm maybe not identifying?

Figure 1:

Figure 2: