Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JAE on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

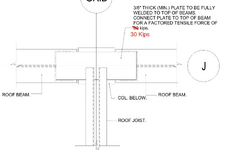

Diaphragm Tie Plate 1

- Thread starter palk7 EIT

- Start date

- Thread starter

- #3

The beam connections to the column would have to be designed for both the vertical shear load as well as the horizontal tie load - which the original designer perhaps didn't do - instead separating the function of both entities to "do their own thing".

The vertical shear beam connections probably have some inherent "give" with short horizontal slotted holes perhaps letting the tie plate do all the horizontal work without any load sharing.

The vertical shear beam connections probably have some inherent "give" with short horizontal slotted holes perhaps letting the tie plate do all the horizontal work without any load sharing.

- Thread starter

- #5

Thats where I was going to, when the beam-column connection is designed for shear as well as axial loads, it should be fine.

However, I was playing with Ram connections and in the program for this particular case, where there are beam on both sides of the column the program doesn't consider both the beams when designing for the axial load, and the connection fails because of the web of the column (Beam to wide flange column web). The other design checks passed except that the column web failed. In this case, if there is a beam on the other side of the column, then this failure on the column web shouldn't occur right?

However, I was playing with Ram connections and in the program for this particular case, where there are beam on both sides of the column the program doesn't consider both the beams when designing for the axial load, and the connection fails because of the web of the column (Beam to wide flange column web). The other design checks passed except that the column web failed. In this case, if there is a beam on the other side of the column, then this failure on the column web shouldn't occur right?

In this case, if there is a beam on the other side of the column, then this failure on the column web shouldn't occur right?

Sounds about right. I assume that we're speaking of a wide flange column and not an HSS column.

- Thread starter

- #7

You should be good then. The only EOR hang-up that I can envision, potentially, is concern for rotational ductility in the beam to column connection. You will often loose that when that connection is designed for axial load transfer. But, then, you often lose it regardless to some degree so I've not been inclined to lose much sleep over it.

SWComposites

Aerospace

The tie plate is presumably there to transfer the load in the beam flange across the connection, rather than forcing it down into the web. Much more efficient if there is significant bending moment in the beam at the connection.

Why would you want to delete the plate?

Why would you want to delete the plate?

- Thread starter

- #10

-

1

- #11

The 3/8 tie plate is there specifically because it is in line with a braced frame. I.e., a collector.if there is a beam on both sides of the grid along this diaphragm line (J) and this line has a vertical brace frame positioned, could this 3/8" tie plate detail eliminated?

PL 3/8x4 Gr. 50 (for a small-ish beam) is good for about 50k ASD. That will hammer a bolt group for smaller beams. Even with bigger beams you'll end up with several columns of bolts in the bolt groups.

You'll see this connection more frequently in roofs framed with bar joists. Specifically subdiaphragms in tilt-up warehouses in earthquake country. In the case of bar joists, there is no other connection to rely on really. You don't want to rip the joist girders' top chords apart out of plane with the transfer load.

In your case with WF beams, the other options are:

1. fully welded shear tabs/clip angles

2. slip critical bolted shear tabs

3. bolted then fully welded shear tabs, which is kindof belt and suspenders and saying "bolts take gravity and welds take axial" (yeah it's more complicated than that but that's the typical explanation of how it works)

4. any combination of the above but with knife plates if it's a HSS column

As you've noted, it is very common to have fabricators and erectors ask for a bolted alternative to these drag connections. Especially on those bigger jobs

Maybe for less chance of the steel fabricator "forgetting" to install it?Why would you want to delete the plate?

Similar threads

- Replies

- 23

- Views

- 3K

- Replies

- 15

- Views

- 10K

- Replies

- 4

- Views

- 730

- Replies

- 0

- Views

- 3K

- Replies

- 7

- Views

- 3K