vutuankhanh

Mechanical

- Mar 25, 2025

- 3

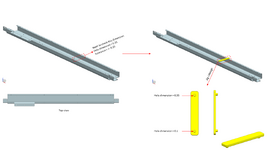

I'm designing a jig to check hole distances on bent sheet metal parts.

For small batches, calipers work. But for mass production, it's slow and tiring.

I need a fixture you can just drop the part into and instantly know if the holes are in spec.

Any ideas for a smart, fast-checking jig design?

Thanks for sharing!

For small batches, calipers work. But for mass production, it's slow and tiring.

I need a fixture you can just drop the part into and instantly know if the holes are in spec.

Any ideas for a smart, fast-checking jig design?

Thanks for sharing!